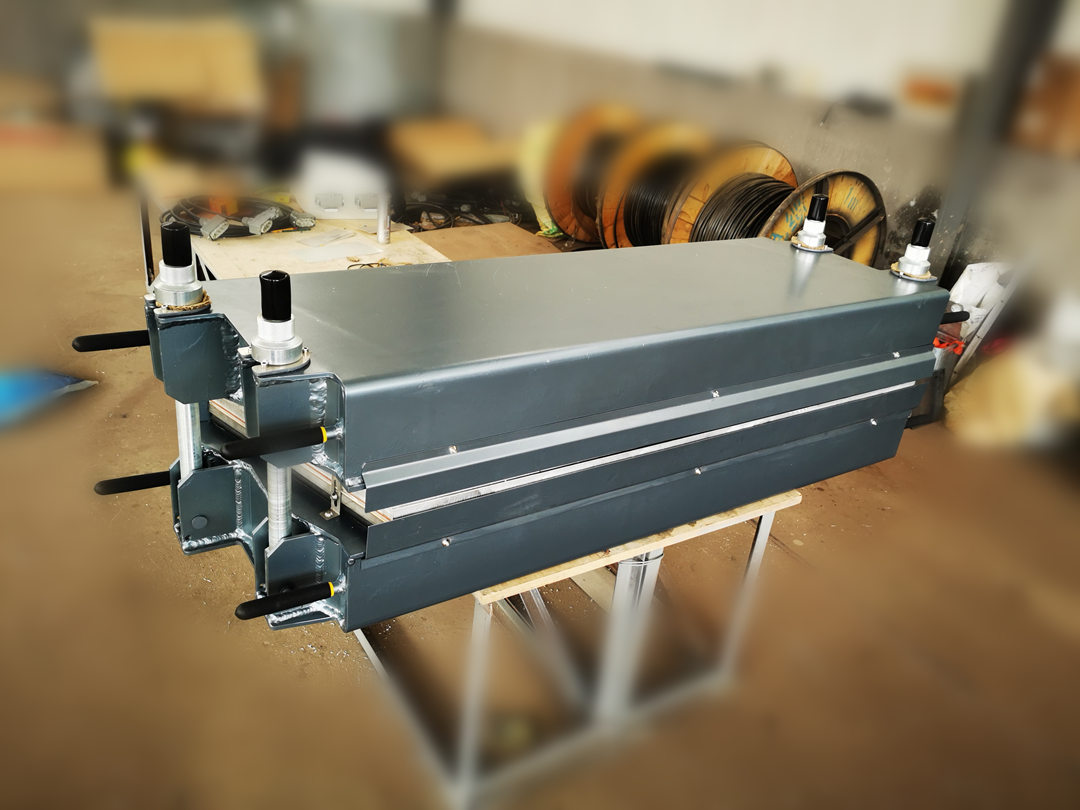

BOX Series Two Pieces Frame Style Cconveyor Belt Vulcanizer

- Two lightweight frames made of welded high-strength aluminum alloy form the upper and lower parts of the press.

- The two sides of the two frames are equipped with handles with rubber sheaths for easy handling;

- Larger models can be equipped with hoisting rings.

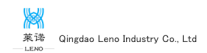

Welded High-strength Aluminum Alloy Frame

- Pressurize frame is welded by the welding process. The whole is a hollow box made of aluminum alloy.

- Lightweight design and built-in handle for easy transport.

- It can be painted according to the color required by the customer, and even the logo of the customer’s company can be posted on the vulcanizing machine

Heating Plate for vulcanizer

- The heating plate is constructed from 6063 aluminum alloy and can be customized to any size with adjustable bias angle.

- The durable and flexible silicone heating element fits tightly to the extruded aluminum alloy plate, allowing for quick and even heating.

- Flexible Heating elements can be customized to customer specified voltage

- The built-in fast water cooling system includes a copper tube that closely conforms to the heating plate for efficient cooling.

- The quick cooling fittings connector is protected by the heating plate to prevent damage from bumps during use.

- A 6-pin high-current aviation durable plug and socket with a locking arrangement prevents disengagement during operation.

Pressure Bag for Vulcanizer

- The durable pressure bag can utilize air, water, or other liquids as its pressurized medium.

- When using air, the pressure can reach up to 1.2Mpa (174PSI), and when using liquid, it can reach over 1.8Mpa (200+ PSI).

- The soft rubber pressure bag perfectly fits the heating plate when internally pressurized, providing uniform pressure.

Electrical Pressurize Pump

- Model lP20l: The pressure bag can be pressurized to the specified pressure within minutes.

- The water pump can also serve as a quick cooling system.

- The pump is equipped with a pressure gauge, pressure safety valve (2.0Mpa), and a manual pressure release switch.

- It replaces manual pressure pumps, reducing labor intensity.

Control Box for belt vulcanizer

- The equipment features a robust and lightweight design, with a painted iron housing that includes a handle and panel cover.

- It can be configured to operate at the voltage specified by the customer, making it suitable for use worldwide.

- The dimensions of the equipment are 450mm x 350mm x 300mm, and it weighs 12kg.

- The power socket includes a dust-proof and moisture-proof cover, and the panel can be customized with the customer’s company logo.

- Adual power supply version is available (optional)

Optional

Air Compressor for Conveyor Belt Vulcanizer

- Small and compact air compressor customized for vulcanizing machines

- Weighs only 23 kilograms.

- Input power of 1.5 kilowatts (2 HP) and Upto 1.2 Mpa (174 PSI) outlet pressure

- With a volume flow rate of 0.25 cubic meters per minute, it can quickly pressurize the vulcanizing machine to the specified pressure.

Optional

Automatic Pressure Control System

- Equipped with a 100-liter liquid storage tank, this system can meet the demands of both pressurization and cooling simultaneously.

- The electric motor is safely enclosed by a sturdy frame, providing ample protection.

- The pressure control valve and gauge enable automatic pressure increases up to a specified level.

- The rubber wheels make it easy to transport and position the system wherever it is needed.

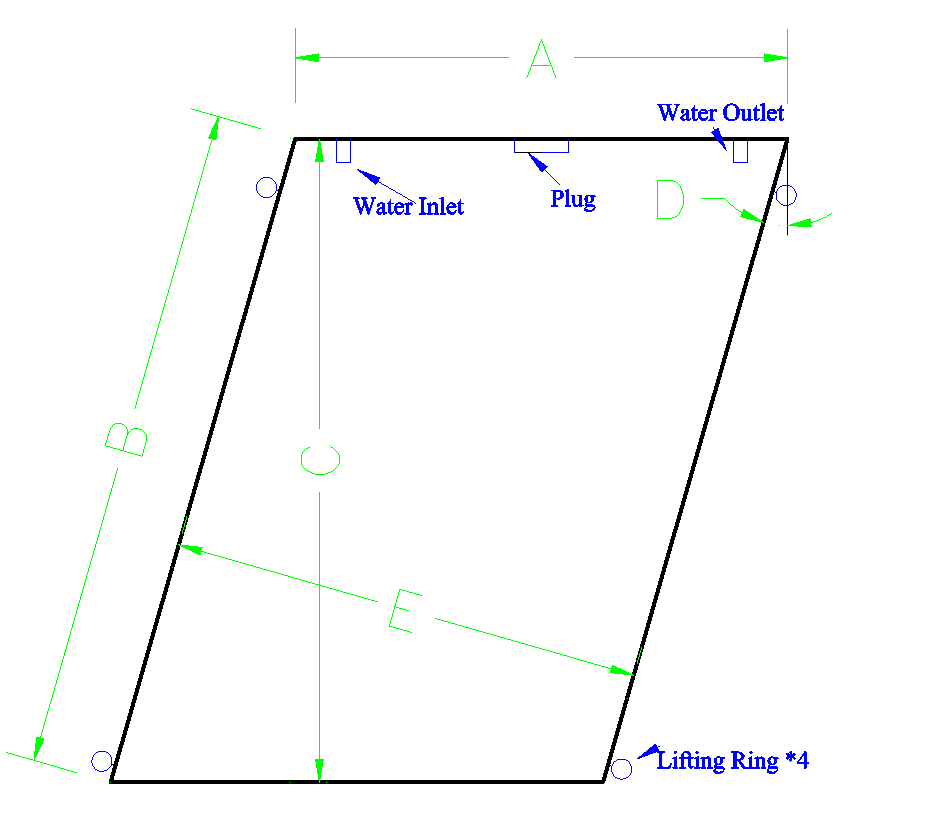

Select The Right BOX Model

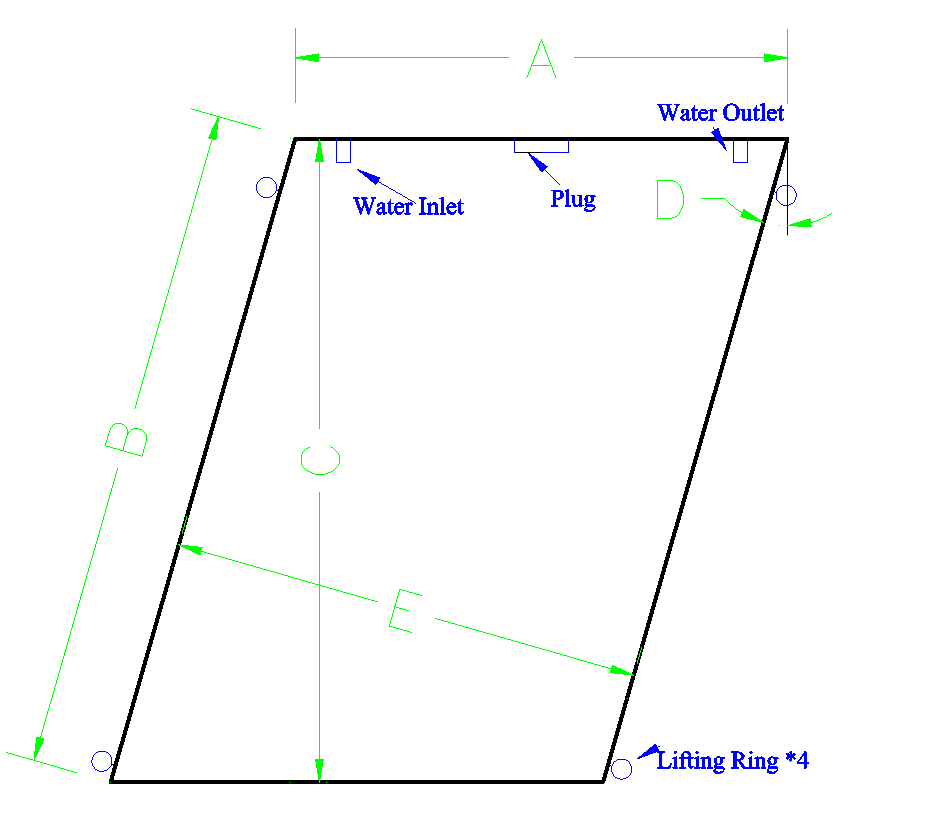

- To properly select a BOX vulcanizer model, dimensions A and B must be determined (see diagram on the right).

- Dimension A, the platen length, is calculated by adding 6 inches (150 mm) for fabric belts or 14 inches (355 mm) for steel cord belts to the belt manufacturer’s recommended splice length.

- Dimension B, the platen width including the bias angle, is calculated by adding 6 inches (150 mm) for fabric belts or 8 inches (200 mm) for steel cord belts to the belt width, then multiplying by 1.07 for a 22 degree bias angle or 1.05 for a 16 degree bias angle.

- Dimensions A and B represent the outside platen dimensions. Find the platen size that corresponds with your figures in the list below. If the size you require is not listed, our sales department can recommend a suitable size. Custom sizes, rectangular configurations, and multiple platen arrangements are available upon request.

Heating Plate Sizes

- ‘A’ represents the length of the platen along the belt.

- ‘E’ represents the heating plate width.

- ‘B’ represents the width of the heating plate across the belt on the bias.

- ‘C’ represents the right angle dimension across the belt, plus edge overlap.

- ‘D’ represents the bias angle.

BOX Conveyor Belt Vulcanizer Data Sheet

| Bias Angle(D) 16° | Belt Width | Frame Height | B | E | C | A | Length | Lower frame weight | Upper frame weight | Platen weight | Total weight |

| Model | mm | mm | mm | mm | mm | mm | mm | Kg | Kg | Kg | Kg |

| BOX 650×350 | 650 | 332 | 780 | 350 | 750 | 364 | 960 | 30 | 23 | 21 | 98 |

| BOX 650×500 | 650 | 342 | 780 | 500 | 750 | 520 | 960 | 38 | 29 | 29 | 131 |

| BOX 650×600 | 650 | 352 | 780 | 600 | 750 | 624 | 960 | 44 | 33 | 35 | 153 |

| BOX 800×350 | 800 | 352 | 940 | 350 | 904 | 364 | 1120 | 36 | 27 | 23 | 111 |

| BOX 800×500 | 800 | 372 | 940 | 350 | 904 | 520 | 1120 | 46 | 36 | 29 | 145 |

| BOX 800×600 | 800 | 382 | 940 | 350 | 904 | 624 | 1120 | 50 | 39 | 43 | 182 |

| BOX 1000×350 | 1000 | 372 | 1145 | 350 | 1101 | 364 | 1325 | 43 | 33 | 32 | 145 |

| BOX 1000×500 | 1000 | 382 | 1145 | 350 | 1101 | 520 | 1325 | 53 | 42 | 43 | 188 |

| BOX 1000×600 | 1000 | 392 | 1145 | 350 | 1101 | 624 | 1325 | 58 | 46 | 50 | 214 |

| BOX 1000×700 | 1000 | 472 | 1145 | 700 | 1101 | 728 | 1345 | 82 | 70 | 59 | 283 |

| BOX 1200×350 | 1200 | 422 | 1355 | 350 | 1303 | 364 | 1535 | 54 | 41 | 37 | 177 |

| BOX 1200×500 | 1200 | 452 | 1355 | 350 | 1303 | 520 | 1535 | 69 | 55 | 50 | 235 |

| BOX 1200×600 | 1200 | 472 | 1355 | 350 | 1303 | 624 | 1535 | 78 | 62 | 60 | 282 |

| BOX 1200×700 | 1200 | 532 | 1355 | 700 | 1303 | 728 | 1555 | 103 | 89 | 70 | 347 |

| BOX 1400×350 | 1400 | 462 | 1560 | 350 | 1500 | 364 | 1740 | 64 | 40 | 41 | 193 |

| BOX 1400×500 | 1400 | 512 | 1560 | 350 | 1500 | 520 | 1760 | 87 | 68 | 58 | 284 |

| BOX 1400×600 | 1400 | 532 | 1560 | 350 | 1500 | 624 | 1760 | 101 | 89 | 71 | 345 |

| BOX 1400×700 | 1400 | 572 | 1560 | 700 | 1500 | 728 | 1760 | 122 | 107 | 81 | 408 |

| BOX 1600×350 | 1600 | 512 | 1770 | 350 | 1701 | 364 | 1950 | 80 | 60 | 46 | 242 |

| BOX 1600×500 | 1600 | 612 | 1770 | 350 | 1701 | 520 | 1970 | 115 | 90 | 65 | 350 |

| BOX 1600×600 | 1600 | 632 | 1770 | 350 | 1701 | 624 | 1970 | 128 | 102 | 78 | 403 |

Mark:

- Specifications are subject to change without notice.

- Integral cooling is standard on all units.

- Total weights do not include the electrical control panel, cable sets, and electric pump and hoses.

- The weight of the lower frame includes the bolts and the pins.

- The total weight includes the 2 heating platens and the pressure bag

Technical data correspond to the 16º models.

- **Custom sizes, rectangular configurations, and multiple platen arrangements are available upon request.**

Standard Packing List Of BOX SERIES TWO PIECES Press

- Welded High-strength Aluminum Alloy Frame

- 3 in one heating platen with build-in water cooling

- Pressure bag

- Thermal/heat insulation board

- Standard Control Box

- Electronic pressure and water cooling pump with pressure protect

- Primary wire/cable & Secondary wire/cable

- Pressure hoses and water cooling hoses

- Clamp bolt sets

- Safety Pins & Safety Bars

- Free spare parts(PT100 sensor)

Optional

- Spare pressure bag

- Spare heating elements

- Spare control box

- Belt clamp device

Have a question about BOX vulcanizing press?

Ask us now.

Our customers can find the suitable model by checking the LENO company catalog. Sometimes, customers need to purchase multiple equipments or need to use a combined heating plate vulcanizer. At this time, directly contact our sales representative to determine the equipment plan as soon as possible!

Testimonial

Feed back From the Customer

What people are saying?

FAQ

Frequently Ask Questions

Customers often ask the following questions before purchasing conveyor belt vulcanizer from LENO

- You can choose the appropriate model from our regular product model list

- We can provide customized services, you need to know the following information.

- The most important thing is to know the size and bias angle of the heating plate of the vulcanizer

- Secondly, we must know the working pressure and voltage used during vulcanization

- Also need to know if there are other needs

Whether it is heating plate for vulcanizing machine, heating element, pressure bag, control panel, high-strength extruded aluminum profile for Cross beam, or whether the customer purchases parts for his own vulcanizing machine, the trader provides for his customers Purchasing spare parts, or purchasing from other vulcanizing machine manufacturers, we are willing to help

- We have some models of products in stock

- It takes about 10-20 natural days to produce a single vulcanizing machine; multiple vulcanizing machines can also be produced within 35 days.

LENO products are very durable and not easily damaged in daily use. The company provides a 12-month warranty for the product. During this period, if the product is damaged under normal use, the company will provide free parts. We can also extend the warranty period according to the needs of customers.

- With the assistance of LENO’s sales staff, the customer determines the model and quantity of the order and other detailed information.

- The customer arranges the advance payment according to the agreement

- Leno company produces the required products according to the order and provides the video and pictures of the products to the customers after the production is completed and the products pass the inspection.

- The customer arranges to pay the final payment, and leno company arranges the delivery

Have a question about our vulcanizing press?

Ask us now.

Our customers can find the suitable model by checking the LENO company catalog. Sometimes, customers need to purchase multiple equipments or need to use a combined heating plate vulcanizer. At this time, directly contact our sales representative to determine the equipment plan as soon as possible!