- Home

- Product

Product

We supply high-quality conveyor belt splice equipment

About Vulacnization on site

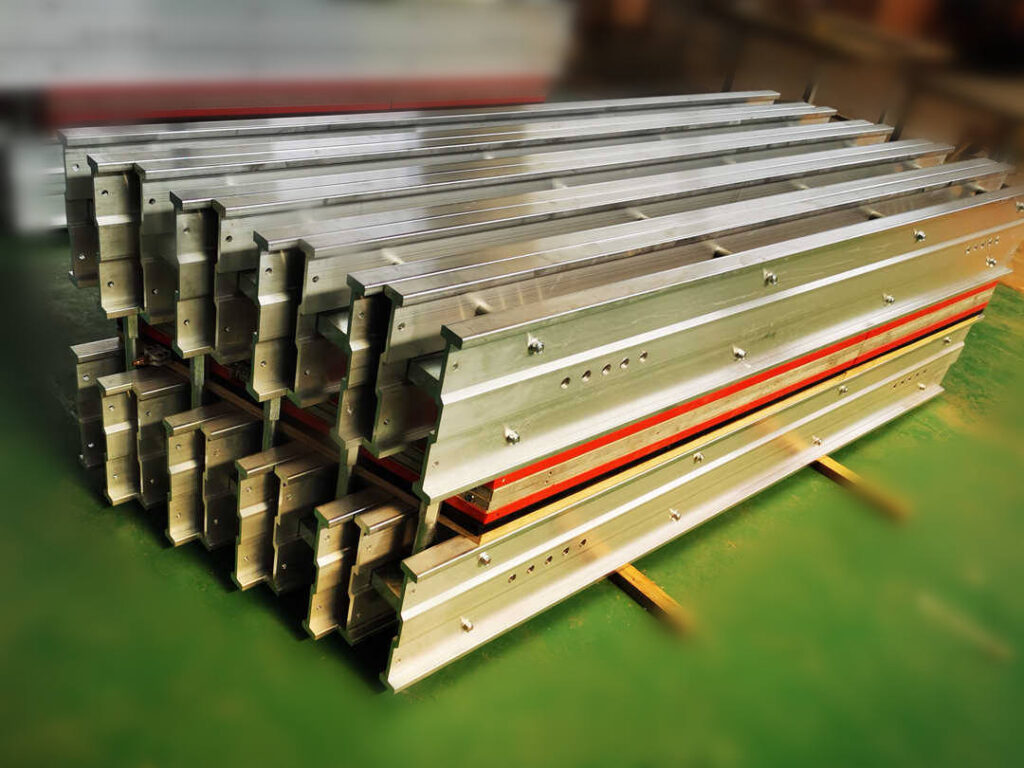

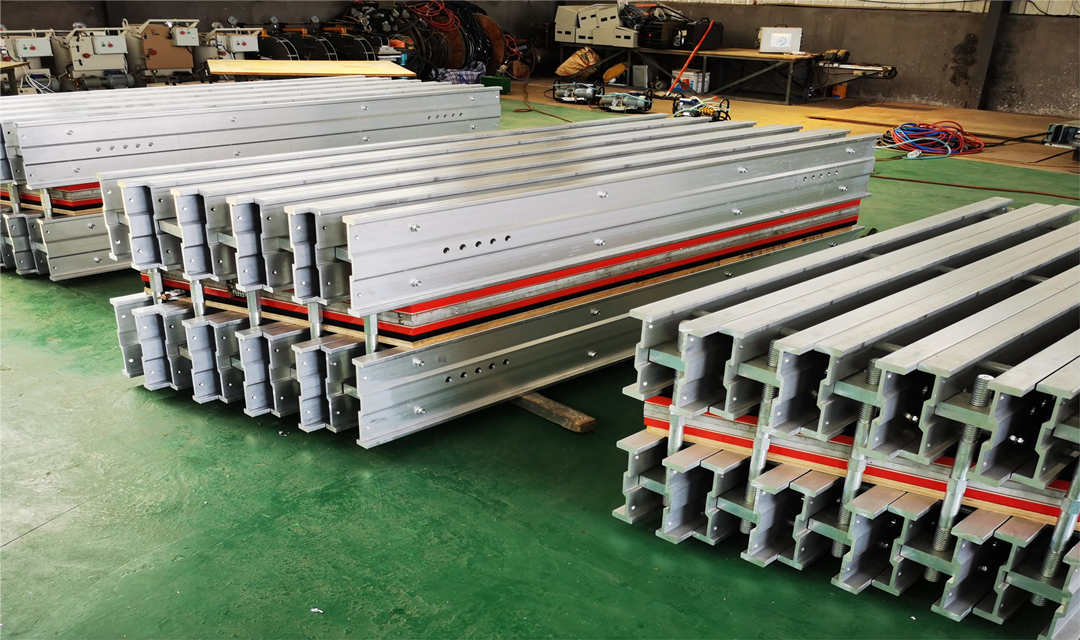

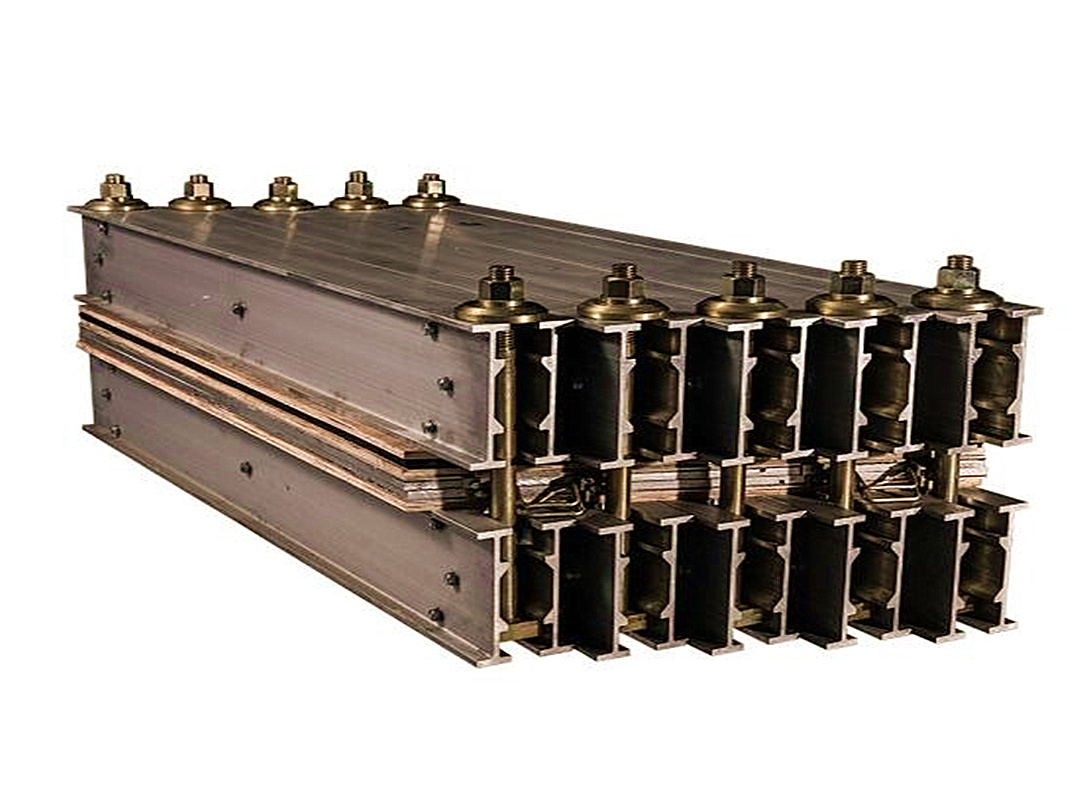

ASVP series Sectional Vulcanizing Press

Main features:

- E-style Cross Beam

- Use Rubber Pressure Bag to get uniform pressure during the whole belt joint splice operation

- Build-in cooling channel within sandwich type heating plates

- Custom flexible silicone heating elements fit perfectly to the size of the heating plate to provide a uniform cure temperature

- Various pressure options, 7 bar (0.7Mpa, 100psi) to 14 bar (1.4Mpa, 200psi)

- (Optional) Automatic temperature and pressure cycle control

- (Optional) Remote monitoring and control system

Get Prices

Send us a message if you have any questions or request a quote.We will be back to you within 12 hours!

Select Sizes

The selection is based on the size of the conveyor belt, the width of the heating plate, the pressure of the vulcanization operation, etc.

Classic Vulcanizer

Sectional Vulcanizing Press

Various configurations are available:

- Usually use the traditional A style cross beam, also can use E-style Cross Beam

- You can choose Rubber Pressure Bag system for vulcanizing machine or traditional pressure plate system with metal frame

- Heating panels can be sandwiched or traditionally separated from insulating planks

- The heating element can be a silicone heating element, or a resistance wire heating sheet

- Plug socket on the heating plate, you can choose a traditional flat socket, or choose a 6-pin connector with a connection lock

Get Prices

Send us a message if you have any questions or request a quote.We will be back to you within 12 hours!

Select Sizes

The selection is based on the size of the conveyor belt, the width of the heating plate, the pressure of the vulcanization operation, etc.

About Vulacnization on site

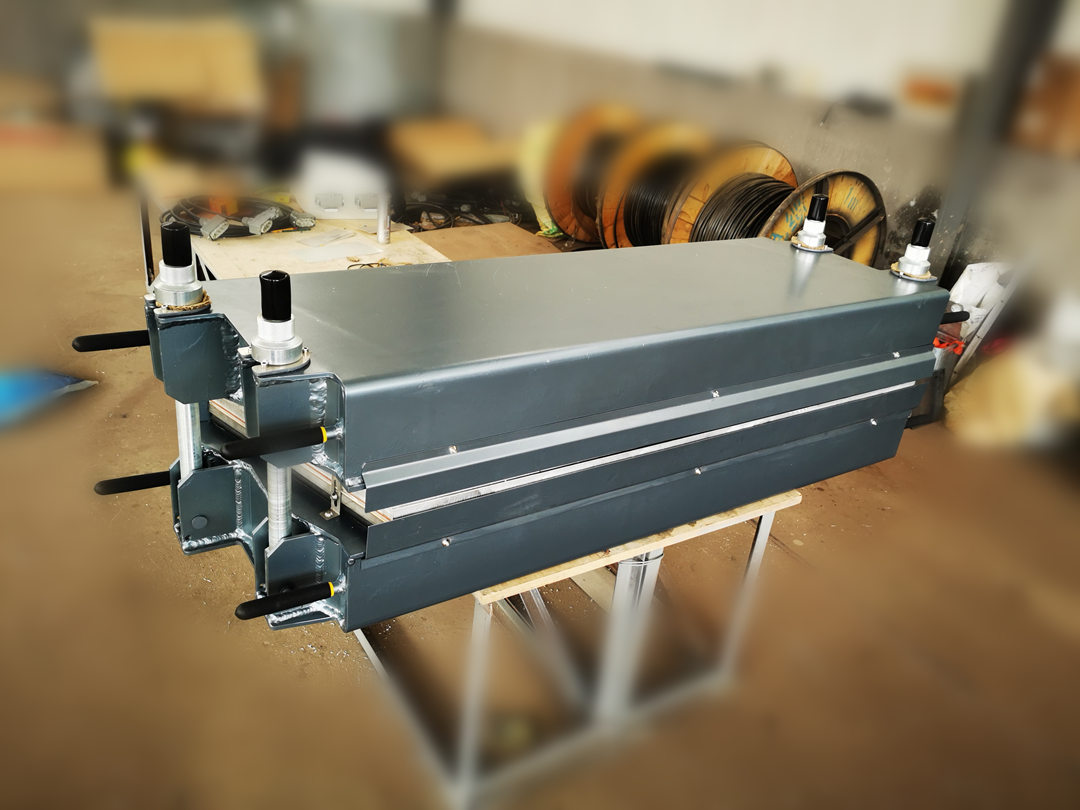

BOX series Two Pieces Frame Type Vulcanizing Press

Main features:

- An integral upper and lower pressure Frame welded by high-strength aluminum alloy plates

The whole vulcanizing machine consists of fewer parts; the upper and lower heating plates and pressure bag can be fixed together with the upper and lower frames

The light model can be easily carried by hand; the heavy model can be transported in place with lifting equipment.

(Optional) 1.2 Mpa Portable Air Compressor System

(Optional) Automatic temperature and pressure control system

Get Prices

Send us a message if you have any questions or request a quote.We will be back to you within 12 hours!

Select Sizes

The selection is based on the size of the conveyor belt, the width of the heating plate, the pressure of the vulcanization operation, etc.

Customize Vulcanizing Machine

Experts in the industry are often not satisfied with just purchasing the models provided by the manufacturers;

They have a deep understanding of the type of curing press they need.

Custom vulcanizing machines usually have the following reasons:

- The width of some conveyor belts is very large (for example, greater than 2100mm), and higher strength requires a larger joint length;

- A large heating plate consists of groups of 3 or more smaller heating plates. To reduce the weight of a single heating plate for easy handling;

- In the customer’s project, conveyor belts of different widths from small to large need to be spliced; smaller heating plates can be used for splicing operations of smaller width conveyor belts;

- You can just purchase or use the existing Cross Beams, without purchasing the entire vulcanizing machine, so as to save valuable budget;

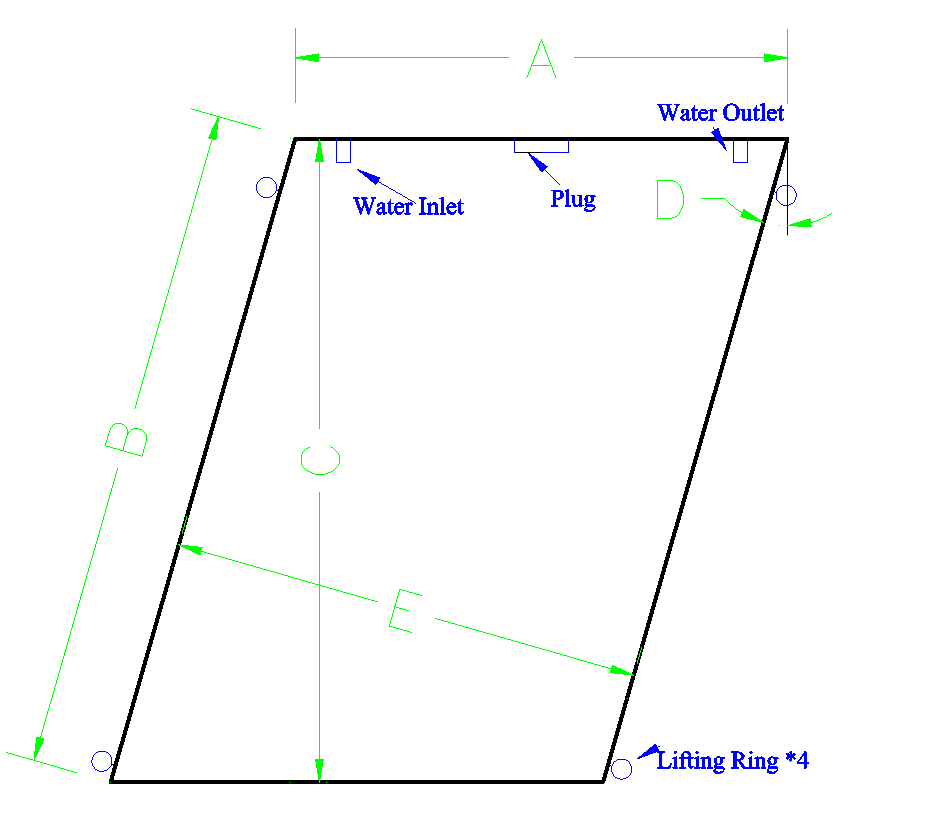

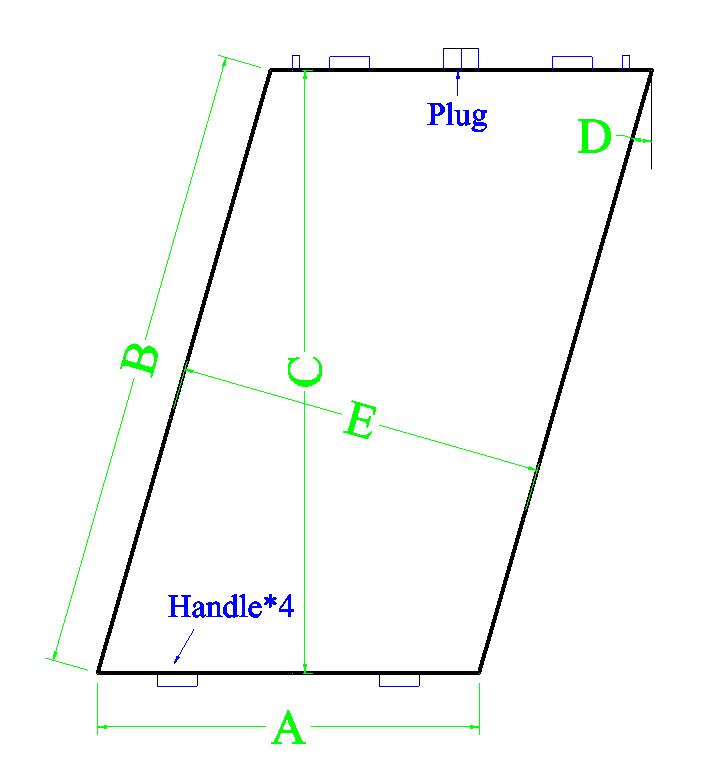

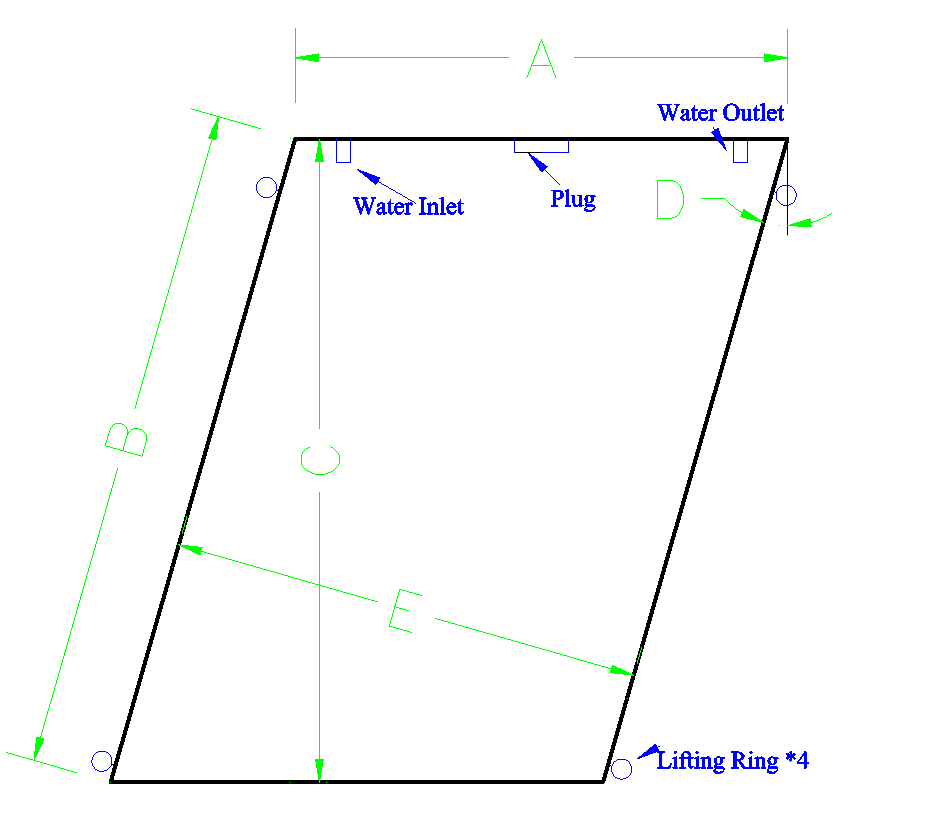

Start with a hand-drawn draft of Conveyor Belt Vulcanizer heating plates

Splice Equipment in Leno

Choose the desired model or customize a vulcanizing machine that meets your project requirements.

Traditional Sectional Vulcanizer

ASVP Joint Vulcanizing Machine

Two pieces frame type vulcanizing press

What we offer

Rubber Belt Splice Relative Products

Don’t go bankrupt, choose the following products

Two Pieces Frame Press

FAQ

Frequently Ask Questions

Customers often ask the following questions before purchasing conveyor belt vulcanizer from LENO

- You can choose the appropriate model from our regular product model list

- We can provide customized services, you need to know the following information.

- The most important thing is to know the size and bias angle of the heating plate of the vulcanizer

- Secondly, we must know the working pressure and voltage used during vulcanization

- Also need to know if there are other needs

Whether it is heating plate for vulcanizing machine, heating element, pressure bag, control panel, high-strength extruded aluminum profile for Cross beam, or whether the customer purchases parts for his own vulcanizing machine, the trader provides for his customers Purchasing spare parts, or purchasing from other vulcanizing machine manufacturers, we are willing to help

- We have some models of products in stock

- It takes about 10-20 natural days to produce a single vulcanizing machine; multiple vulcanizing machines can also be produced within 35 days.

LENO products are very durable and not easily damaged in daily use. The company provides a 12-month warranty for the product. During this period, if the product is damaged under normal use, the company will provide free parts. We can also extend the warranty period according to the needs of customers.

- With the assistance of LENO’s sales staff, the customer determines the model and quantity of the order and other detailed information.

- The customer arranges the advance payment according to the agreement

- Leno company produces the required products according to the order and provides the video and pictures of the products to the customers after the production is completed and the products pass the inspection.

- The customer arranges to pay the final payment, and leno company arranges the delivery

Testimonial

FeedbackbFrom the Customer

What people are saying?

Have a question about our vulcanizing press?

Ask us now.

Our customers can find the suitable model by checking the LENO company catalog. Sometimes, customers need to purchase multiple equipments or need to use a combined heating plate vulcanizer. At this time, directly contact our sales representative to determine the equipment plan as soon as possible!

Conveyor Belt Vulcanizing Press Manufacturer

At Leno, we take pride in supplying our clients with world-class and high-quality standard and custom-made belt joint press

Get a free quote.

Purchase a vulcanizing press?

Contact us and let our sales team assist you.

What we Do?

Conveyor Belt Joint Equipment & Supplies Provider

Qingdao Leno Industry Co.,Ltd (LENO) is a Qingdao-based factory that produces conveyor belt vulcanizing presses and joint vulcanizers. Our primary focus is on providing high-quality products and worry-free after-sales service to clients around the world. Our clients, including company founders, on-site managers, and purchasing managers, prioritize product quality and expect on-time delivery. We stand out from the competition due to our flexible communication, comprehensive product quality assurance, and commitment to building long-term relationships with our clients.

Splice Equipment in Leno

Choose the desired model or customize a vulcanizing machine that meets your project requirements.

Traditional Sectional Vulcanizer

ASVP Combination Joint Vulcanizing Machine

Two pieces frame type vulcanizing press

Ask Us About Our Products

At Leno, we offer over 200 press models. Request a free quote from us today!

What we offer

Rubber Belt Splice Relative Products

Don’t go bankrupt, choose the following products

Two Pieces Frame Press

Why choose leno?

Partner You Can Rely ON

Respect the objective reality of customers, suitable products are better products

High-Quality Materials

We use only the highest quality materials in the construction of our vulcanizing machines, ensuring long-lasting durability and reliable performance. Our machines are built to withstand even the toughest environments and applications.

Expertise and Experience

Our team has years of expertise and experience in the vulcanizing machine industry, allowing us to offer advanced solutions that meet the highest standards of quality and performance. You can trust us to deliver the results you need for your project.

Competitive Pricing

Our vulcanizing machines are priced competitively, offering excellent value for your investment. We're committed to providing affordable solutions that don't compromise on quality, allowing you to get the most out of your budget.

Excellent Customer Service

At our company, we pride ourselves on providing excellent customer service. Our team is always available to answer your questions and provide support whenever you need it. We're committed to ensuring your complete satisfaction with our products and services.

Customizable Solutions

We offer a wide range of customizable vulcanizing machines to fit your unique project needs. Our team can work with you to design and build a machine that perfectly matches your requirements

Low Maintenance Requirements

Our vulcanizing machines require minimal maintenance, reducing downtime and increasing productivity. With simple maintenance requirements, our machines are easy to keep in top working condition for years to come.

Easy to Use

Our vulcanizing machines are designed with ease of use in mind, featuring intuitive controls and simple operation. You don't need to be an expert to operate our machines - anyone can quickly learn to use them effectively.

Fast Heating Times

Our vulcanizing machines feature advanced heating elements that provide fast and efficient heating, allowing you to complete projects quickly and efficiently. With our machines, you can get your work done faster without sacrificing quality.

Custom Your Vulcanizing Press

How to customize a suitable vulcanizing machine? You can start with a hand-drawn size drawing of the heating plate!

Testimonial

FeedbackbFrom the Customer

What people are saying?

Trusted by Worldwide Clients