Custom Conveyor Belt Vulcanizer

Only a few steps are needed to customize the conveyor belt vulcanizer

- View the catalog of Leno;

- Inform Leno’s sales team if you have special needs;

- Both parties confirm specifications and prices.

- Arrange production and delivery

Table Of Contents For This Page

It is not easy to introduce all aspects of Conveyor Belt Vulcanizer, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Applications For Conveyor Belt Vulcanizer

Conveyor belt vulcanizers find applications in various industries where conveyor belts are an integral part of the production, transportation, and material handling processes. Here are some general applications for conveyor belt vulcanizers

Mining and Quarrying

Conveyor belts are extensively used in the mining and quarrying industries to transport materials like coal, ore, gravel, and minerals. Vulcanizers are used to repair and splice conveyor belts in these harsh environments to ensure continuous and efficient material transportation.

Bulk Material Handling

Industries dealing with bulk materials, such as agriculture, construction, and logistics, rely on conveyor belts to move products like grains, aggregates, sand, and construction materials. Vulcanizers help maintain the integrity of the conveyor belts and prevent disruptions in material handling operations.

Manufacturing

Conveyor belts are used in manufacturing processes to transport products along assembly lines or between different production stages. Vulcanizers are used to repair and join conveyor belts in manufacturing facilities, ensuring seamless production flow.

Food Processing

Conveyor belts are used in the food industry for tasks like sorting, packaging, and transporting food products. Conveyor belt vulcanizers help maintain hygiene standards by repairing and splicing belts used in food processing and packaging operations.

Airport Baggage Handling

Conveyor systems at airports are used to transport passenger luggage efficiently. Vulcanizers are employed to repair and splice conveyor belts in baggage handling systems to prevent delays and disruptions in airport operations.

Recycling and Waste Management

Conveyor belts are utilized in recycling and waste management facilities to transport recyclable materials and waste products for processing and disposal. Vulcanizers ensure the continuous functioning of these conveyor systems.

Power Generation

Conveyor belts are used to transport coal and other materials in power plants. Vulcanizers are used to repair and splice belts used in coal handling systems to maintain a steady supply of fuel for power generation.

Cement and Concrete Industry

Conveyor belts are essential for transporting raw materials, such as limestone and cement, within cement plants. Vulcanizers are used to keep these belts in optimal working condition.

Automotive Industry

Conveyor belts are used in automotive manufacturing for tasks like assembly line production and material transport. Vulcanizers help ensure uninterrupted production in automotive plants.

Textile Industry

Conveyor belts are utilized in textile manufacturing processes to transport fabrics and materials between different stages of production. Vulcanizers help maintain the efficiency of these conveyor systems.

Parcel and Package Delivery

Conveyor systems are a critical component of parcel and package delivery services, helping sort and transport packages efficiently. Vulcanizers ensure reliable conveyor belt operation in distribution centers.

Chemical and Pharmaceutical

Conveyor belts are used in chemical and pharmaceutical manufacturing for material handling and product transportation. Vulcanizers play a role in maintaining the integrity of these conveyor systems.

These are just a few examples of the wide range of industries that benefit from conveyor belt vulcanizers. The primary goal is to ensure the smooth operation of conveyor systems by repairing and splicing conveyor belts as needed, minimizing downtime, and maximizing efficiency.

General Hot Selling Product

At LENO INDUSTRY, we understand the significance of providing solutions that align with market demands. Alongside our commitment to excellence, we take pride in introducing you to our range of cutting-edge conveyor belt vulcanizers. With our focus on quality and reliability, we offer three distinct types of conveyor belt vulcanizers, each designed to meet specific industry requirements

ASVP Sectional Vulcanizing Press

- Compact and lightweight design.

- Fast heating and cooling speeds, with uniform temperature and pressure distribution.

- Simple structure for easy maintenance.

- Strong and equipped with sufficient safety features.

We are proud to introduce the ASVP sectional vulcanizing press, which has undergone continuous improvements and now demonstrates outstanding performance compared to similar products.

***Model name ASVP means Advanced Sectional Vulcanizing Press***

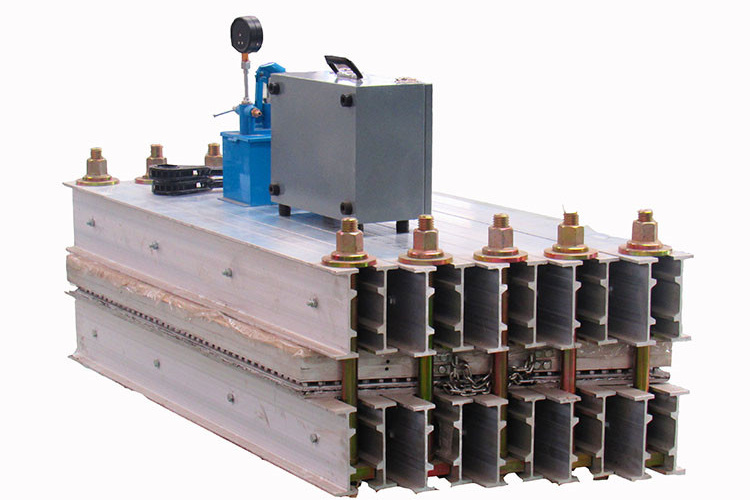

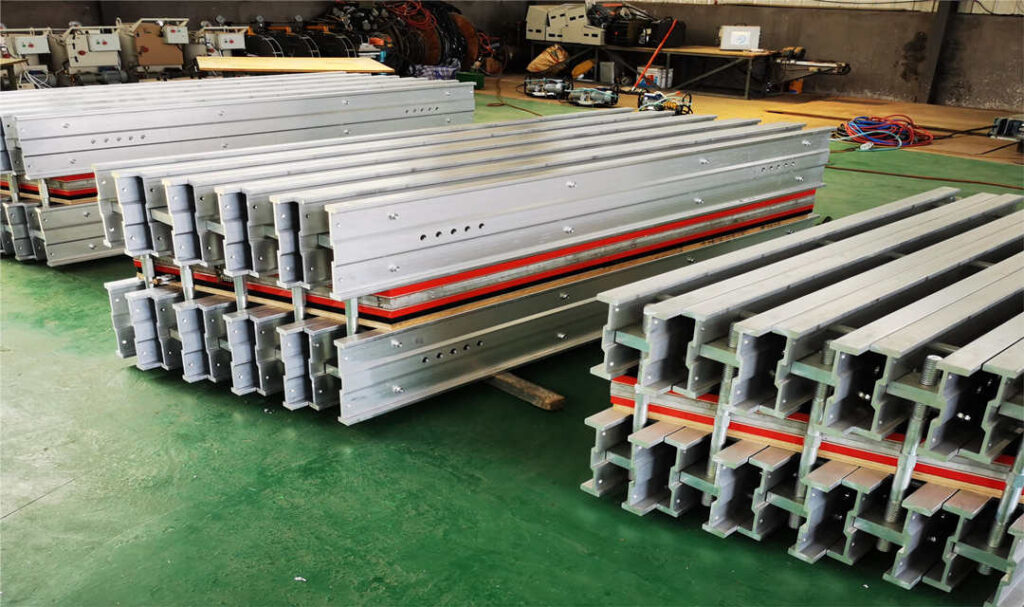

Classic Sectional Vulcanizing Press

- Heating plates can be heated using traditional heating elements or silicon heating elements.

- There are also two types of silicon heating elements available – lightweight design or sandwich-style heating plates, which are similar to the ASVP vulcanizer.

- The pressure system can use the traditional aluminum base plate with a metal frame and screw press plate or the modern rubber pressure bag.

- Although a manual pressure pump is sometimes used, most customers opt for an electric pressure pump that, when used with a quick water cooling system, significantly reduces the time required for conveyor belt splicing.

The Classic Sectional Vulcanizing Press is a durable conveyor belt vulcanizer that has been around for over 40 years. Its main feature is the use of a sturdy A-type crossbeam. Over the years, the Classic Sectional Vulcanizing Press has undergone several developments, and there are now various configuration options available.

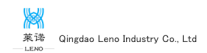

BOX SERIES TWO PIECES FRAME STYLE BELT VULCANIZING PRESS

- Two lightweight frames made of welded high-strength aluminum alloy form the upper and lower parts of the press.

- The two sides of the two frames are equipped with handles with rubber sheaths for easy handling;

- Larger models can be equipped with hoisting rings.

The BOX series conveyor belt vulcanizer press features a streamlined structure with fewer components, making it the lightest curing press for conveyor belts. Its user-friendly design has garnered popularity in developed markets such as Europe and the United States.

Estimated Cost Analysis For purchase a Vulcanizer Press from Leno China?

When estimating the cost of purchasing a vulcanizer press from Leno China, it’s important to consider several factors that can contribute to the overall cost.

Keep in mind that these costs can vary based on the type and size of the vulcanizer press, the manufacturer, and other specific details.

Here’s a general breakdown of the potential costs to consider:

Cost of Vulcanizer Press

The cost of the vulcanizer press itself is the primary expense. This can vary widely based on factors such as the type (e.g., portable, industrial, specialized), capacity, features, and brand. Prices can range from $ 1000 dollars to tens of thousands of dollars.

Shipping Fees

Shipping costs depend on the size, weight, and shipping method chosen. The most cost-effective mode of transportation is typically the Less than Container Load (LCL) sea freight option. For instance, transporting a standard-sized vulcanizing machine from Qingdao Port, China to Durban Port, South Africa, usually costs just a few tens of dollars using LCL sea freight. However, opting for air freight for the same vulcanizing machine would require several thousand dollars.

Import fees

Import fees, customs duties, taxes, and other charges associated with bringing the equipment into your country should also be factored in. These costs can significantly impact the total expense.Customers can inquire with their own shipping agents while also seeking input from LENO Company for reference on the aforementioned import fees. This will help them choose the most suitable agency. For instance, clearing the mentioned standard-sized vulcanizing machine through customs to a warehouse in Durban might cost around $300. Customers can then pick up the shipment from the freight company’s warehouse to their own facility.

To get an accurate cost estimate, it’s recommended to reach out to multiple manufacturers in China,

request detailed quotations, and clarify all potential costs involved.

Additionally, research the supplier’s credibility, read reviews, and gather as much information as possible before making a purchasing decision.

Contact Leno’s Sales Team, and get a reply in one day!

The Process Flow & Duration Estimation

The process of purchasing a vulcanizer from Leno Company in China involves several stages, each with its own timeline.

Please note that the durations provided are approximate and can vary based on factors such as communication efficiency, customization requirements, shipping, and unforeseen delays.

Here’s a general overview of the process flow and estimated duration:

Stage 1: Pre-sales Negotiation (1-4 weeks)

Initial Inquiry and Communication (1-2 weeks):

- Contact Leno Sales Team to inquire about vulcanizer options, specifications, and pricing.

- Exchange initial emails or messages to gather information and discuss requirements.

Quotation and Customization Discussion (1-2 weeks):

- Leno provides a detailed quotation based on your requirements.

- If customization is needed, discuss details such as specifications, features, and any additional costs.

- Clarify payment terms, shipping options, and warranty details.

Order Placement and Payment (1 week):

- The customer approval the order and provided the necessary documentation.

- Make the initial payment as per the agreed terms.

Stage 2: Order Production (2-4 weeks)

Manufacturing and Production (1-3 weeks):

- Received the initial payment means the order started to us.

- Leno manufactures or customizes the vulcanizer according to your specifications.

- This stage’s duration varies based on the complexity and workload.

Quality Control and Testing (0-1 weeks):

- Leno performs quality checks and testing to ensure the vulcanizer meets the specified standards.

Stage 3: Post-sales and Delivery (4-8 weeks)

Final Payment and Shipping Arrangements (1-2 weeks):

- Complete the final payment as per the agreement.

- Leno arranges shipping details, including mode of transportation (sea or air), shipping schedule, and documentation.

Shipping Transit (2-4 weeks):

- Shipping duration depends on the chosen method (sea or air) and the destination.

- Shipping from Qingdao port China to Durban port South Africa costs 25 -30 days on the sea

Customs Clearance and Import Process (1-3 weeks):

- Customs clearance and import process time can vary by country and import regulations.

Delivery to Destination (1 week):

- Delivery time from the port of entry to your facility or designated location.

Installation and Testing (1 week):

- If required, schedule installation and training by Leno’s technicians.

The entire process from initial inquiry to the delivery and installation of the vulcanizer can take approximately 1 to 3 months or more,

depending on the specific circumstances.

Clear communication with Leno throughout each stage is essential,

and it’s advisable to account for potential delays in customs, shipping, or unforeseen circumstances.

Want to know how to compress lead times?

Discover efficiency.

Streamline processes.

Cut delays.

Elevate productivity.

Contact us now for insights into optimizing lead times and enhancing operations.

The Basic Knowledge About Conveyor Belt Vulcanizer

Explore the fundamentals of conveyor belt vulcanizers.

Learn about splicing techniques, heating processes, and maintenance.

Dive into the essential knowledge for efficient and reliable conveyor belt operations

How does the vulcanization process contribute to the longevity of conveyor belts?

Discover how the vulcanization proc

What does the future hold for conveyor belt vulcanizer technology and advancements?

Discover the exciting advancements

Are there any notable case studies or success stories related to conveyor belt vulcanizers?

Unlocking Success: Notable Case Stu

How can one choose the right conveyor belt vulcanizer for their specific needs?

Choosing the Perfect Conveyor Belt

What are the current trends and innovations in conveyor belt vulcanizer technology?

Current Trends and Innovations in C

What safety considerations should be taken into account when using a vulcanizer?

In the pursuit of operational excel

What are the advantages and benefits of using a conveyor belt vulcanizer?

Maximizing Efficiency with Conveyor

Where are Conveyor Belt Vulcanizers Commonly Used in Industrial Settings?

In the fast-paced world of industri

What are the Different Types of Conveyor Belt Vulcanizers Available in the Market? A Comprehensive Guide

Discover the various types of conve

What is a conveyor belt vulcanizer and how does it function?

A conveyor belt vulcanizer is a spe

The Common Pitfalls When Purchasing Vulcanizer

Before buying a vulcanizer, conduct thorough research and avoid these common pitfalls to ensure your investment is wise and sustainable.

- Ignoring Mismatched Suitability

- Opting for Low Quality and Cheap Options

- Overlooking Post-Sales Support

- Neglecting Maintenance Costs

- Inadequate Knowledge of Regulatory Requirements

In the grand opera of industry, the vulcanizer is but one note, yet it harmonizes with the symphony of your dreams. Navigate the treacherous waters, and your choice shall be the crescendo of success, resounding through the corridors of time.

A Brief Self-Nomination, Why Choose LENO Vulcanizer?

Choose LENO Vulcanizer for unparalleled quality and expertise. Our state-of-the-art technology, experienced team, and commitment to customer satisfaction set us apart. With a track record of reliability and innovation, we deliver solutions that elevate your operations. Experience excellence with LENO Vulcanizer.

In today’s fast-paced industrial landscape, efficiency, reliability, and innovation are the cornerstones of success. When it comes to optimizing conveyor systems, repairing conveyor belts, and ensuring smooth material handling processes, the choice of equipment and technology provider is paramount. This article delves into why LENO Vulcanizer stands as the premier choice for businesses seeking top-tier vulcanization solutions.

Our Unwavering Commitment to Customer Satisfaction

Customer satisfaction is at the core of everything we do. We work closely with our clients to understand their needs and challenges. This customer-centric approach allows us to deliver solutions that not only meet expectations but exceed them. Your success is our success.

Reliability: A Hallmark of LENO Vulcanizer

Reliability is a hallmark of LENO Vulcanizer. Our equipment is built to withstand the demands of various industries, ensuring uninterrupted production processes. With LENO Vulcanizer, you can count on a dependable partner for your conveyor belt splicing needs.

Innovation: Pioneering Solutions for Industry Challenges

The industrial landscape is ever-evolving, and so are the challenges it presents. LENO Vulcanizer stays at the forefront of innovation, constantly developing new solutions to address industry-specific challenges. We pride ourselves on being pioneers in our field.

Experience Excellence with LENO Vulcanizer

In conclusion, choosing LENO Vulcanizer means choosing excellence. Our state-of-the-art technology, experienced team, commitment to customer satisfaction, reliability, and innovation come together to provide unmatched vulcanization solutions. Elevate your operations and experience the difference with LENO Vulcanizer.

In the realm of conveyor belt vulcanization, LENO Vulcanizer stands as the epitome of excellence. With a focus on quality, innovation, and customer satisfaction, we are your trusted partner for optimizing conveyor systems and elevating your operations. Experience excellence with LENO Vulcanizer, where technology and expertise come together to drive success.

FAQ

The FAQs when purchase conveyor belt vulcanizer

Customers often ask the following questions before purchasing conveyor belt vulcanizer from LENO

- You can choose the appropriate model from our regular product model list

- We can provide customized services, you need to know the following information.

- The most important thing is to know the size and bias angle of the heating plate of the vulcanizer

- Secondly, we must know the working pressure and voltage used during vulcanization

- Also need to know if there are other needs

Whether it is heating plate for vulcanizing machine, heating element, pressure bag, control panel, high-strength extruded aluminum profile for Cross beam, or whether the customer purchases parts for his own vulcanizing machine, the trader provides for his customers Purchasing spare parts, or purchasing from other vulcanizing machine manufacturers, we are willing to help

- We have some models of products in stock

- It takes about 10-20 natural days to produce a single vulcanizing machine; multiple vulcanizing machines can also be produced within 35 days.

LENO products are very durable and not easily damaged in daily use. The company provides a 12-month warranty for the product. During this period, if the product is damaged under normal use, the company will provide free parts. We can also extend the warranty period according to the needs of customers.

- With the assistance of LENO’s sales staff, the customer determines the model and quantity of the order and other detailed information.

- The customer arranges the advance payment according to the agreement

- Leno company produces the required products according to the order and provides the video and pictures of the products to the customers after the production is completed and the products pass the inspection.

- The customer arranges to pay the final payment, and leno company arranges the delivery

Testimonial

Feed back From the Customer

What people are saying?

Have a question about our vulcanizing press?

Ask us now.

Our customers can find the suitable model by checking the LENO company catalog. Sometimes, customers need to purchase multiple equipments or need to use a combined heating plate vulcanizer. At this time, directly contact our sales representative to determine the equipment plan as soon as possible!