A conveyor belt vulcanizer is a specialized industrial machine used for the process of vulcanization, which involves bonding and strengthening conveyor belts. Vulcanization is a method of joining and solidifying rubber components using heat and pressure to create a durable and resilient bond.

Here’s how a conveyor belt vulcanizer functions:

1. Preparation of Belt Ends:

1. Preparation of Belt Ends:

– The first step involves preparing the ends of the conveyor belt by cutting them to precise lengths and angles. This ensures a proper and secure splice.

2. Application of Vulcanizing Solution:

– A vulcanizing solution, often in the form of specialized adhesives or uncured rubber, is applied to the prepared belt ends. This solution acts as a bonding agent during the vulcanization process.

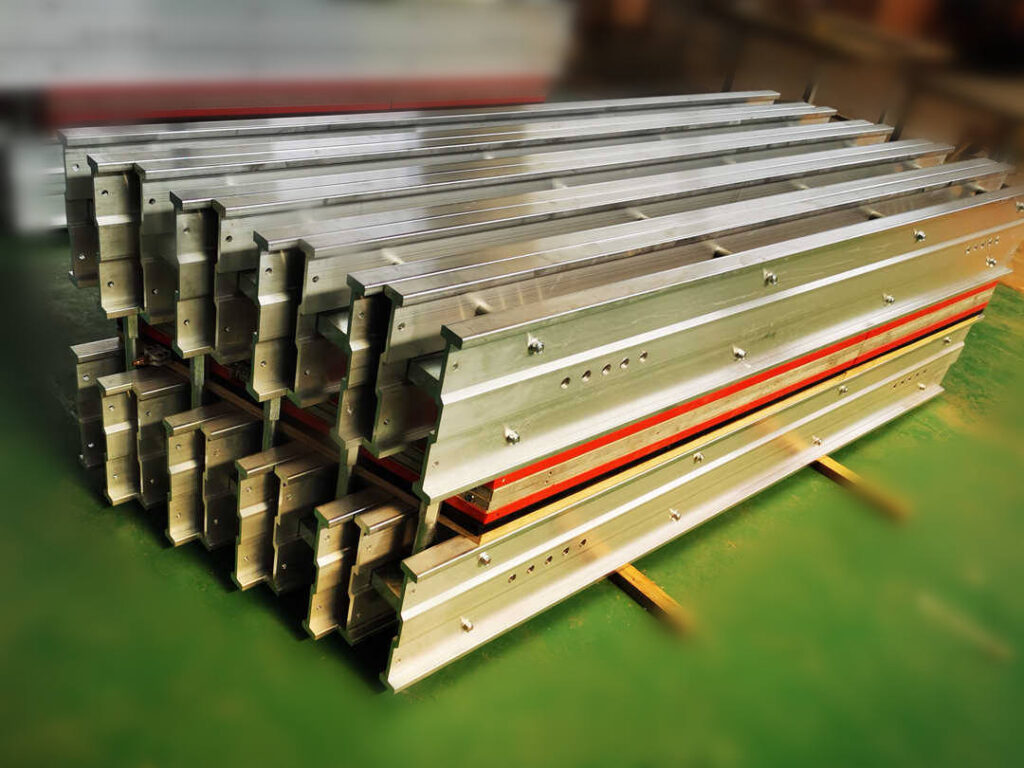

3. Alignment and Clamping:

– The belt ends are then aligned using specific guides or templates to ensure they are positioned accurately. Clamps are applied to hold the ends firmly in place.

4. Heating Elements:

– Conveyor belt vulcanizers are equipped with heating elements, which generate heat necessary for vulcanization. These elements can be in the form of plates, platens, or other configurations.

5. Application of Pressure:

– In addition to heat, pressure is applied to the belt ends. This is crucial for ensuring a strong and uniform bond. The level of pressure applied is carefully controlled based on the type and thickness of the conveyor belt.

6. Vulcanization Process:

– The vulcanization process begins as the heating elements raise the temperature of the belt ends. The vulcanizing solution acts as a catalyst, causing the rubber to chemically bond and form a seamless joint.

7. Cooling and Curing:

– After the vulcanization process, the joint is allowed to cool down. This helps in solidifying the bond further. The cured joint is now ready for operational use.

8. Final Inspection:

– Once the vulcanization process is complete, a final inspection is conducted to ensure that the splice is of high quality and meets industry standards.

The end result of this process is a conveyor belt with a strong, durable splice that can withstand the rigors of industrial operations. This ensures smooth and efficient material handling in various industries, including manufacturing, mining, logistics, and more.