In the fast-paced world of industrial operations, ensuring the reliability and durability of conveyor belts is of paramount importance. Conveyor belt vulcanizers play a crucial role in this process, acting as the unsung heroes that keep industries moving. Let’s delve into the heart of this indispensable equipment.

Understanding Conveyor Belt Vulcanizers

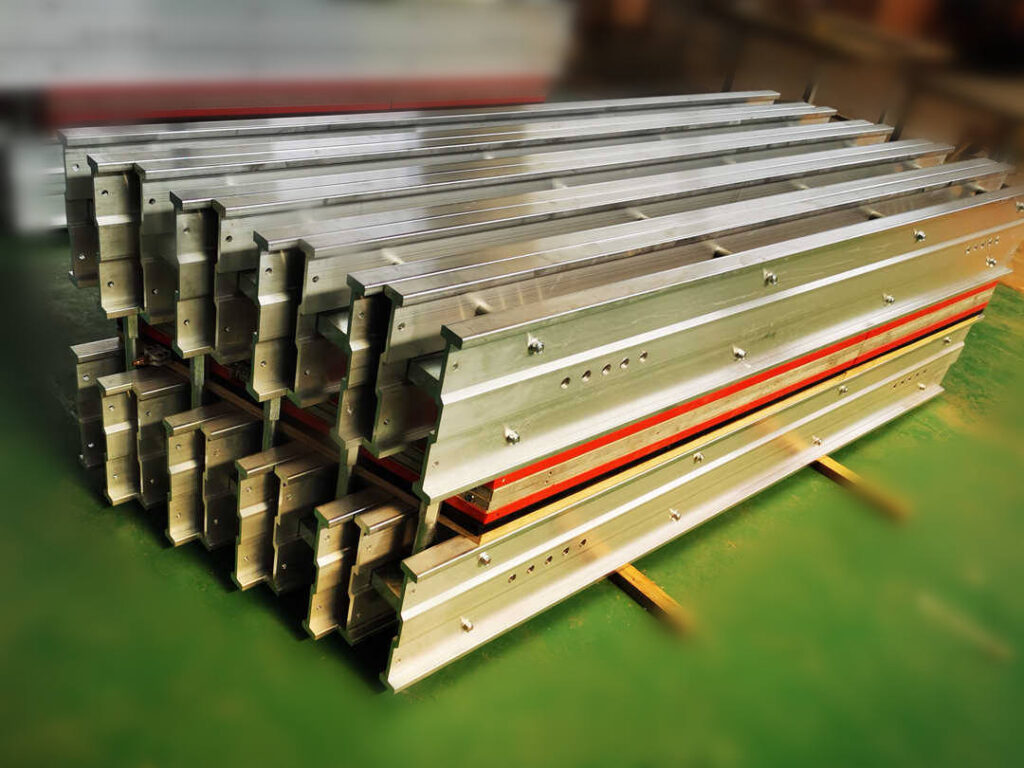

What are Conveyor Belt Vulcanizers?

Conveyor belt vulcanizers are specialized machines designed to repair and maintain conveyor belts. They work by applying heat and pressure to bonding agents, allowing for seamless repairs and splicing.

Importance in Industrial Settings

In the realm of industry, time is money. Conveyor belt vulcanizers drastically reduce downtime by providing swift and efficient solutions to belt damage. This ensures that operations remain uninterrupted, ultimately contributing to increased productivity and profitability.

Types of Conveyor Belt Vulcanizers

Hot Vulcanizers

Hot vulcanizers use high temperatures to facilitate the bonding process. They are ideal for heavy-duty applications and are particularly effective in industries that require durable and long-lasting conveyor belts.

Cold Vulcanizers

Cold vulcanizers, on the other hand, operate at lower temperatures and are suitable for a wide range of applications. They are preferred when heat-sensitive materials are involved, preventing any potential damage.

Applications in Industrial Settings

Mining Industry

In the demanding world of mining, conveyor belt vulcanizers are a lifeline. They ensure that materials are transported efficiently, even in the harshest conditions, thus preventing costly delays.

Manufacturing Plants

Manufacturing plants rely on conveyor belts for the seamless movement of goods. Vulcanizers play a vital role in ensuring that these belts remain operational, minimizing disruptions in production.

Construction Sites

Construction sites often require the movement of heavy materials, making conveyor belts indispensable. Vulcanizers enable quick repairs, ensuring that projects progress smoothly.

Recycling Facilities

Recycling facilities handle a diverse range of materials, necessitating reliable conveyor systems. Vulcanizers guarantee that these systems remain in optimal condition, contributing to the sustainability efforts of recycling plants.

Benefits of Using Conveyor Belt Vulcanizers**

Enhanced Safety

Maintaining the integrity of conveyor belts is crucial for preventing accidents. Vulcanizers ensure that belts are in top condition, reducing the risk of mishaps.

Increased Efficiency

Smoothly operating conveyor belts are essential for maintaining workflow efficiency. Vulcanizers play a pivotal role in achieving this, enhancing overall operational performance.

Cost-Effectiveness

By prolonging the lifespan of conveyor belts, vulcanizers save industries substantial costs associated with frequent replacements. This makes them a sound investment for any industrial operation.

Maintenance and Care of Vulcanizers

Regular Inspections

Routine inspections are essential to identify any potential issues early on. This proactive approach helps prevent unexpected breakdowns and ensures consistent performance.

Proper Cleaning Techniques

Keeping vulcanizers clean and well-maintained is crucial for their longevity. Implementing proper cleaning practices is a simple yet effective way to extend the lifespan of this equipment.

Choosing the Right Conveyor Belt Vulcanizer

Consideration of Industry Needs

Each industry has its unique requirements. Selecting a vulcanizer that aligns with the specific needs of the industry is essential for optimal performance.

Sizing and Capacity

Choosing a vulcanizer with the appropriate size and capacity ensures that it can handle the demands of the operation effectively. This prevents overworking and extends the life of the equipment.

Conclusion

In the grand tapestry of industrial operations, conveyor belt vulcanizers are the unsung heroes that hold it all together. Their significance in ensuring the seamless flow of materials cannot be overstated. By investing in these invaluable machines, industries are poised for enhanced efficiency, safety, and cost savings.

FAQs

What industries benefit most from conveyor belt vulcanizers?

Conveyor belt vulcanizers find widespread use in industries such as mining, manufacturing, construction, and recycling facilities.

Are there any safety precautions to take when using vulcanizers?

Yes, safety is paramount. Operators should receive proper training, and safety protocols must be followed diligently to prevent accidents.

How often should vulcanizers be inspected?

Routine inspections should be conducted at regular intervals, preferably as part of a scheduled maintenance program.

Can a conveyor belt vulcanizer be customized for specific needs?

Yes, many manufacturers offer customization options to cater to the unique requirements of different industries.

What are the common issues that can arise with vulcanizers?

Common issues include wear and tear, damage to heating elements, and issues related to pressure application. Regular maintenance helps identify and address these problems promptly.