Discover the exciting advancements in conveyor belt vulcanizer technology and get insights into what the future holds for this crucial industry. Stay ahead with the latest innovations.

Introduction

In an era driven by technological advancements, the conveyor belt vulcanizer industry is poised for a revolution. The demand for efficient and reliable conveyor systems is escalating across various sectors, from manufacturing to logistics. This surge in demand has paved the way for rapid advancements in vulcanization technology. In this article, we will delve into the current state of conveyor belt vulcanizer technology and explore the exciting prospects that lie ahead.

The Evolution of Conveyor Belt Vulcanizer Technology

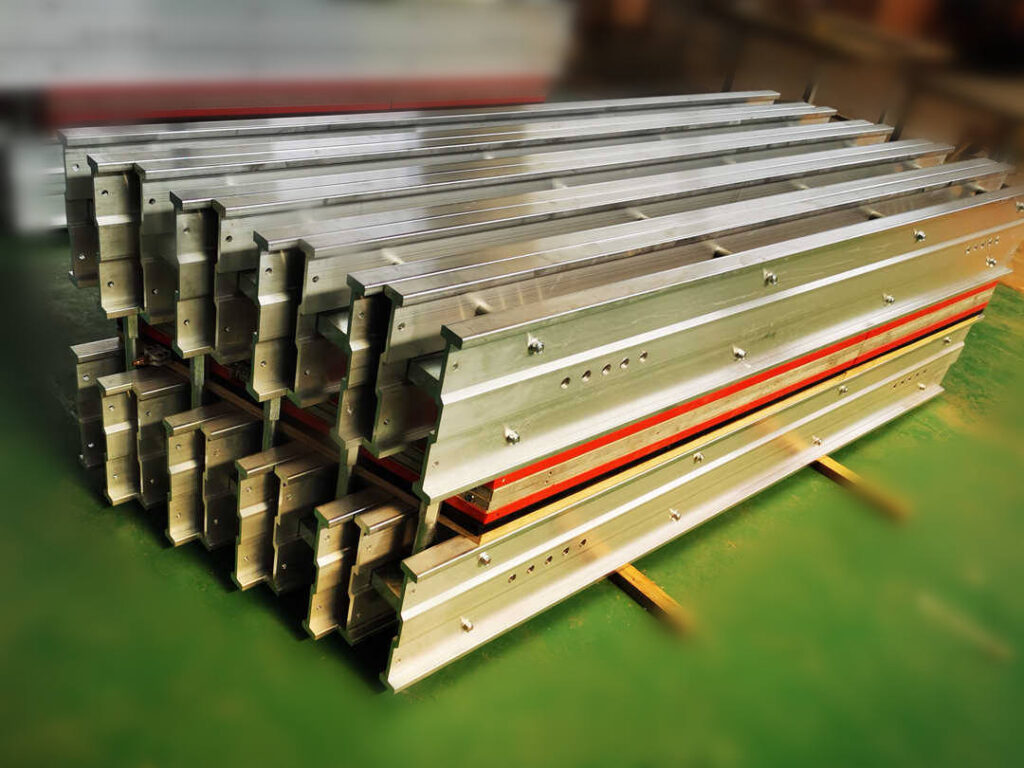

The conveyor belt vulcanizer industry has come a long way since its inception. From manual processes to automated systems, the evolution has been nothing short of remarkable. Today, state-of-the-art vulcanizers boast precision engineering, allowing for seamless splicing and repairs. These machines have become the backbone of industries relying on conveyor systems for smooth operations.

Automation: A Game-Changer

Automation is set to be the cornerstone of future conveyor belt vulcanizer technology. Advanced sensors and artificial intelligence are being integrated to enable real-time monitoring and adjustments. This not only enhances operational efficiency but also minimizes downtime due to maintenance.

Sustainable Solutions for a Greener Future

With environmental concerns taking center stage, the conveyor belt vulcanizer industry is making significant strides towards sustainability. Innovations in materials and processes are reducing the environmental footprint of vulcanization. Eco-friendly compounds and energy-efficient technologies are becoming standard, aligning with global efforts towards a greener future.

Smart Integration and IoT Connectivity

The integration of Internet of Things (IoT) in conveyor belt vulcanizer technology is a paradigm shift. Smart sensors gather data on various parameters, enabling predictive maintenance and optimizing performance. This connectivity ensures that vulcanizers operate at peak efficiency, with minimal intervention.

Enhanced Safety Features

Safety is paramount in any industrial setting. Future conveyor belt vulcanizers are being equipped with advanced safety features. From fail-safes to comprehensive training modules, manufacturers are prioritizing the well-being of operators and personnel working in proximity to these machines.

FAQs

How does conveyor belt vulcanization work?

Conveyor belt vulcanization involves the process of splicing two belt ends together using heat, pressure, and specialized adhesives. This creates a seamless joint, ensuring smooth operation.

What are LSI Keywords and why are they important in outlining?

LSI Keywords, or Latent Semantic Indexing Keywords, are terms related to the main keyword. They provide context and relevance to the content. Using LSI Keywords in headings and subheadings helps improve the overall SEO performance.

Are there any environmental benefits to advanced vulcanization technology?

Absolutely. Advanced vulcanization technology often incorporates eco-friendly compounds and energy-efficient processes, reducing the environmental impact of conveyor belt production and maintenance.

How can IoT connectivity benefit conveyor belt vulcanizers?

IoT connectivity enables real-time monitoring and data collection. This data can be used for predictive maintenance, optimizing performance, and reducing unplanned downtime.

What safety measures should be in place when operating a conveyor belt vulcanizer?

Operators should receive comprehensive training on the safe operation of vulcanizers. Additionally, machines should be equipped with fail-safes and emergency stop features to ensure the well-being of personnel.

How can businesses stay ahead in adopting the latest conveyor belt vulcanizer technology?

Staying informed about industry trends, attending conferences, and building relationships with reputable manufacturers are key steps in adopting the latest conveyor belt vulcanizer technology.

Conclusion

The future of conveyor belt vulcanizer technology is an exciting frontier of innovation. With automation, sustainability, and safety at its core, the industry is poised for unprecedented growth. Staying abreast of these advancements will be paramount for businesses looking to thrive in a rapidly evolving industrial landscape.