Discover how the vulcanization process enhances the durability of conveyor belts. Learn about the key steps involved and the benefits it brings to industrial applications.

Introduction

In the world of industrial machinery, the longevity of conveyor belts is paramount. These essential components keep production lines moving efficiently. One crucial technique that significantly enhances their durability is vulcanization. But what exactly is vulcanization, and how does it contribute to the extended lifespan of conveyor belts? In this comprehensive guide, we’ll delve into the intricacies of this process, shedding light on its impact and benefits.

The Essence of Vulcanization

What is Vulcanization?

Vulcanization is a chemical process that transforms natural or synthetic rubber into a more durable and resilient material. This method was pioneered by Charles Goodyear in the mid-19th century and revolutionized the rubber industry. Through the application of heat, pressure, and sulfur, the rubber undergoes a molecular transformation, resulting in improved elasticity, strength, and resistance to environmental factors.

Key Steps in Vulcanizing Conveyor Belts

To vulcanize a conveyor belt, several precise steps are followed:

- Preparation of the Belt Surface

The conveyor belt’s surface is meticulously cleaned to remove any contaminants or impurities that could hinder the vulcanization process.

- Application of Vulcanizing Solution

A specialized vulcanizing solution is evenly spread over the surface of the belt. This solution contains sulfur and other compounds essential for the vulcanization reaction.

- Layering with Reinforcement Materials

Depending on the specific application, additional layers or reinforcement materials may be added to enhance strength and durability.

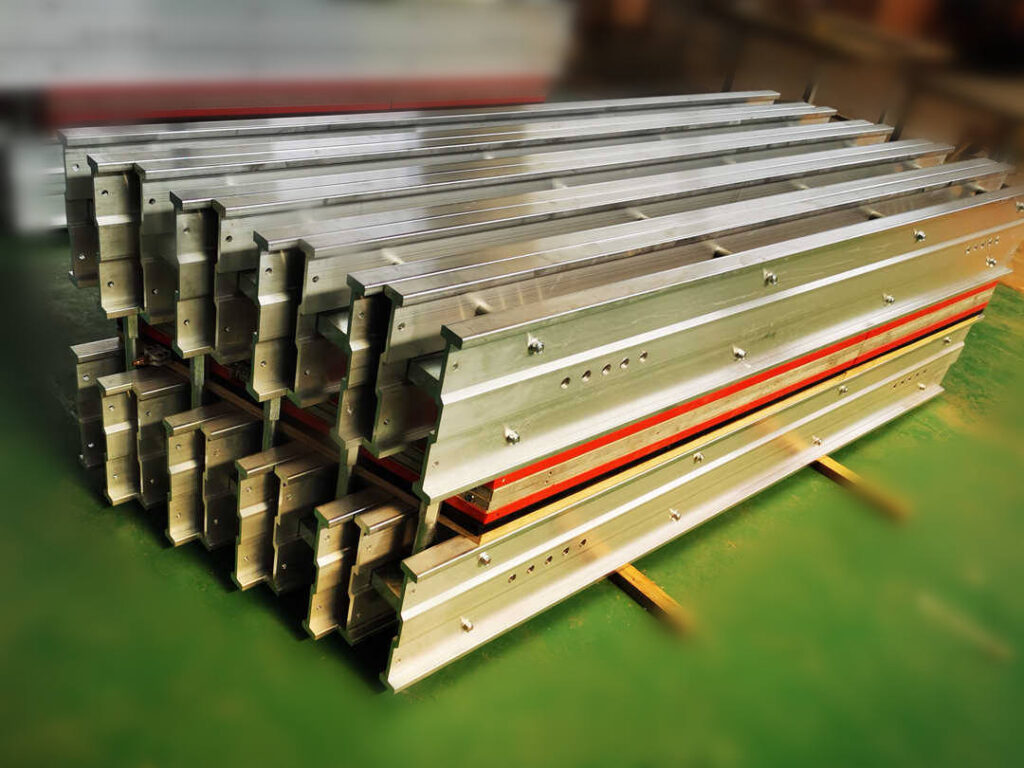

- Heat and Pressure Application

The belt is placed in a vulcanizing press, which applies both heat and pressure. This initiates the chemical reaction, causing the rubber to undergo the vulcanization process.

- Cooling and Curing

Once vulcanization is complete, the belt is allowed to cool gradually, ensuring the newly formed material retains its enhanced properties.

Advantages of Vulcanized Conveyor Belts

Exceptional Durability

Vulcanization significantly increases the lifespan of conveyor belts. The resulting material is more resistant to wear and tear, making it ideal for heavy-duty industrial applications.

Enhanced Resistance to Environmental Factors

Vulcanized belts exhibit superior resistance to moisture, chemicals, and extreme temperatures. This makes them suitable for a wide range of industries and environments.

Improved Flexibility and Elasticity

Conveyor belts subject to vulcanization maintain their flexibility, allowing for smoother operation and reduced stress on mechanical components.

Cost-Effectiveness in the Long Run

While the vulcanization process may entail an initial investment, the extended lifespan of the conveyor belt translates to substantial cost savings over time.

FAQs

Q: How long does the vulcanization process typically take?

A: The duration of vulcanization varies depending on factors like belt thickness and the specific materials used. On average, it can take anywhere from a few hours to a day.

Q: Can all types of conveyor belts undergo vulcanization?

A: Vulcanization is most effective on rubber-based belts, whether natural or synthetic. Other materials may not respond as favorably to the process.

Q: Are there any environmental considerations with vulcanization?

A: The vulcanization process itself is environmentally neutral. However, proper disposal of any used materials is crucial to ensure eco-friendliness.

Q: Can vulcanized belts be repaired if they become damaged?

A: Yes, vulcanized belts can often be repaired by reapplying the vulcanization process to the damaged area.

Q: Are there any safety precautions to take during vulcanization?

A: It’s essential to follow industry-standard safety protocols, including proper ventilation and personal protective equipment, when performing vulcanization.

Q: What industries benefit the most from vulcanized conveyor belts?

A: Industries with high-demand, heavy-duty applications, such as mining, manufacturing, and agriculture, benefit greatly from the extended lifespan of vulcanized belts.

Conclusion

The vulcanization process stands as a testament to human ingenuity in enhancing the longevity and performance of essential industrial components. By subjecting conveyor belts to this transformative process, we ensure they can withstand the rigors of demanding applications, ultimately leading to increased productivity and cost savings for industries around the world.