In the realm of industrial machinery, efficiency is paramount. Each component plays a crucial role in ensuring operations run seamlessly, and one such integral element is the conveyor belt vulcanizer. This specialized equipment holds the key to maintaining the integrity and longevity of conveyor belts, thereby contributing significantly to the overall productivity of various industries.

Unveiling the Conveyor Belt Vulcanizer

What is a Conveyor Belt Vulcanizer?

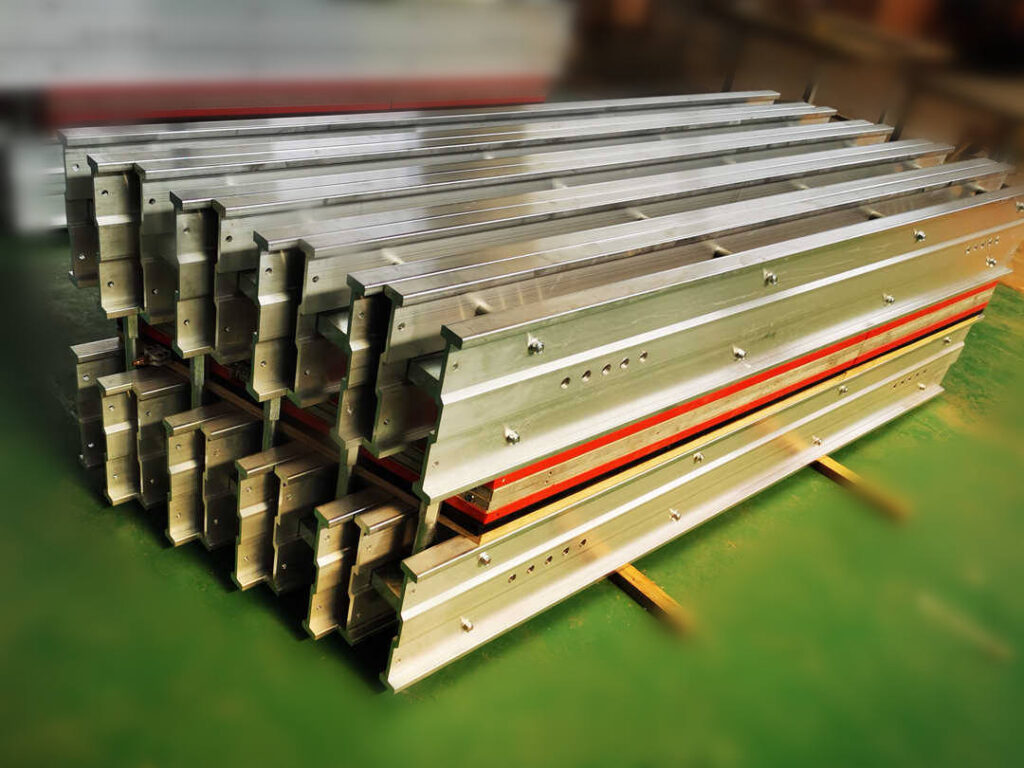

A conveyor belt vulcanizer is a mechanical apparatus designed for the vital task of splicing conveyor belts. This process involves joining two ends of a conveyor belt to form a continuous loop, ensuring smooth and uninterrupted material transportation.

The Functionality Unraveled

1. Preparation of the Belt Ends

Before the vulcanization process commences, meticulous preparation of the belt ends is imperative. This involves stripping the belt’s top cover to expose the fabric plies, ensuring a clean and even surface for the splice.

2. Application of Heat and Pressure

The conveyor belt vulcanizer operates on the principle of heat and pressure application. It comprises heated plates and pressure elements that are strategically positioned over the prepared belt ends.

3. Vulcanization Process

Upon securing the belt ends in position, the vulcanization process initiates. The application of heat softens the belt’s cover and fabric, allowing them to meld together seamlessly. Simultaneously, the pressure ensures uniformity in the splicing process, resulting in a robust and durable joint.

4. Cooling Phase

Post-vulcanization, a controlled cooling phase is initiated. This step is critical in solidifying the splice and ensuring its structural integrity. The gradual reduction of temperature is carefully monitored to prevent any thermal shock to the belt.

Industries Benefiting from Conveyor Belt Vulcanizers

The versatility of conveyor belt vulcanizers renders them indispensable across various industries. These include:

– Mining: Conveyor systems are the backbone of mining operations, facilitating the transportation of extracted materials. Vulcanized belts guarantee smooth movement, even in the harshest mining environments.

– Manufacturing: In manufacturing facilities, conveyor belts are ubiquitous in production lines. The seamless splicing achieved through vulcanization minimizes downtime and maximizes output.

– Construction: Construction sites rely heavily on conveyor systems for the efficient movement of materials. Vulcanized belts are instrumental in ensuring uninterrupted workflows.

– Agriculture: Conveyor belts find applications in agricultural processes, from grain handling to packaging. Vulcanization ensures reliability even in the most demanding agricultural settings.

The Significance of Quality Vulcanization

Investing in a high-quality conveyor belt vulcanizer is paramount for any industry reliant on conveyor systems. A well-executed splice not only enhances operational efficiency but also prolongs the lifespan of the belt, ultimately resulting in cost savings.

Conclusion: Elevating Operational Efficiency

In the intricate tapestry of industrial processes, conveyor belt vulcanizers stand as a testament to the relentless pursuit of efficiency. Their role in ensuring the seamless operation of conveyor systems cannot be overstated. By understanding the intricacies of this vital equipment, industries can make informed decisions that lead to heightened productivity and cost-effective operations.