Discover the various types of conveyor belt vulcanizers on the market. This detailed guide provides expert insights, FAQs, and recommendations to help you make an informed choice.

Introduction

In the world of conveyor systems, ensuring their durability and efficiency is paramount. This is where conveyor belt vulcanizers play a crucial role. But with a myriad of options available, choosing the right one can be overwhelming. This comprehensive guide aims to demystify the choices, providing you with valuable insights to make an informed decision.

Types of Conveyor Belt Vulcanizers

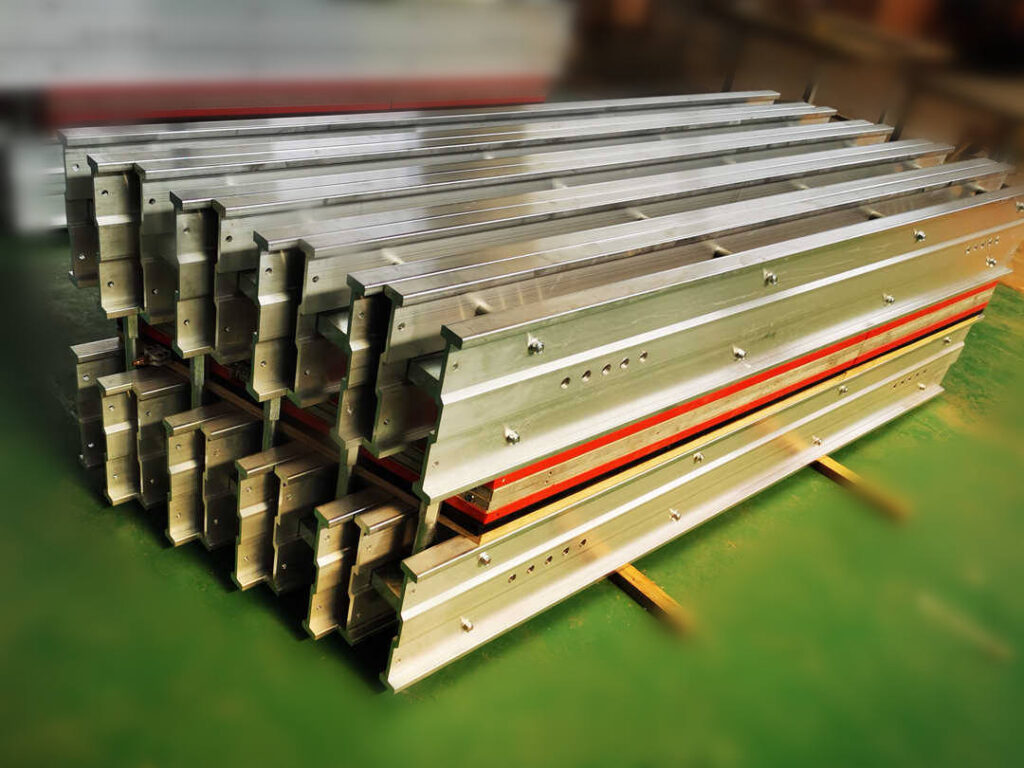

1. Hot Vulcanizing Presses

Hot vulcanizing presses are the industry standard for splicing conveyor belts. They utilize heat and pressure to effectively bond the ends of a belt, ensuring a seamless connection. These vulcanizers come in various sizes to accommodate different belt widths and thicknesses.

2. Cold Vulcanizing Presses

Cold vulcanizing presses are a more versatile option, as they do not rely on high temperatures. Instead, they use special adhesives to bond the belt ends. While not as permanent as hot vulcanizing, they are suitable for certain applications and can be a quicker solution for minor repairs.

3. Portable Vulcanizing Equipment

For on-site repairs and maintenance, portable vulcanizing equipment is indispensable. These compact units offer flexibility and convenience, allowing technicians to address issues without dismantling the entire conveyor system. They are especially valuable in industries where downtime is costly.

4. Mechanical Fasteners

In situations where vulcanizing may not be feasible, mechanical fasteners provide a reliable alternative. These metal or plastic connectors are applied to the belt ends, offering a secure joint. While not as seamless as vulcanizing, they are durable and can be a practical solution for certain applications.

5. Electric Vulcanizing Presses

Electric vulcanizing presses combine the efficiency of hot vulcanizing with precise temperature control. They are suitable for high-demand operations where consistency in splicing is critical. These advanced machines offer programmable settings for different belt materials.

FAQs

What factors should I consider when choosing a vulcanizer?

When selecting a vulcanizer, consider factors such as the type of conveyor system, belt material, and application. Additionally, assess the size and accessibility of the work area.

Can I use cold vulcanizing for all types of belts?

Cold vulcanizing is best suited for fabric and steel cord belts. It may not be as effective for belts with a high degree of heat resistance.

How often should I conduct belt splicing and repairs?

The frequency of belt splicing and repairs depends on factors like conveyor usage, material abrasiveness, and operating conditions. Regular inspections can help identify issues early.

Are portable vulcanizing units easy to operate?

Portable vulcanizing units are designed for user-friendly operation. They typically come with clear instructions and require minimal training.

What are the advantages of using mechanical fasteners?

Mechanical fasteners offer quick and reliable solutions for joining belts. They also allow for easy belt replacement and repairs.

Is hot vulcanizing suitable for heat-sensitive belts?

Hot vulcanizing may not be suitable for belts that are sensitive to high temperatures. In such cases, alternative methods like cold vulcanizing should be considered.

Conclusion

Choosing the right conveyor belt vulcanizer is a critical decision in ensuring the longevity and efficiency of your conveyor system. By understanding the various types available and their applications, you can make an informed choice tailored to your specific needs.