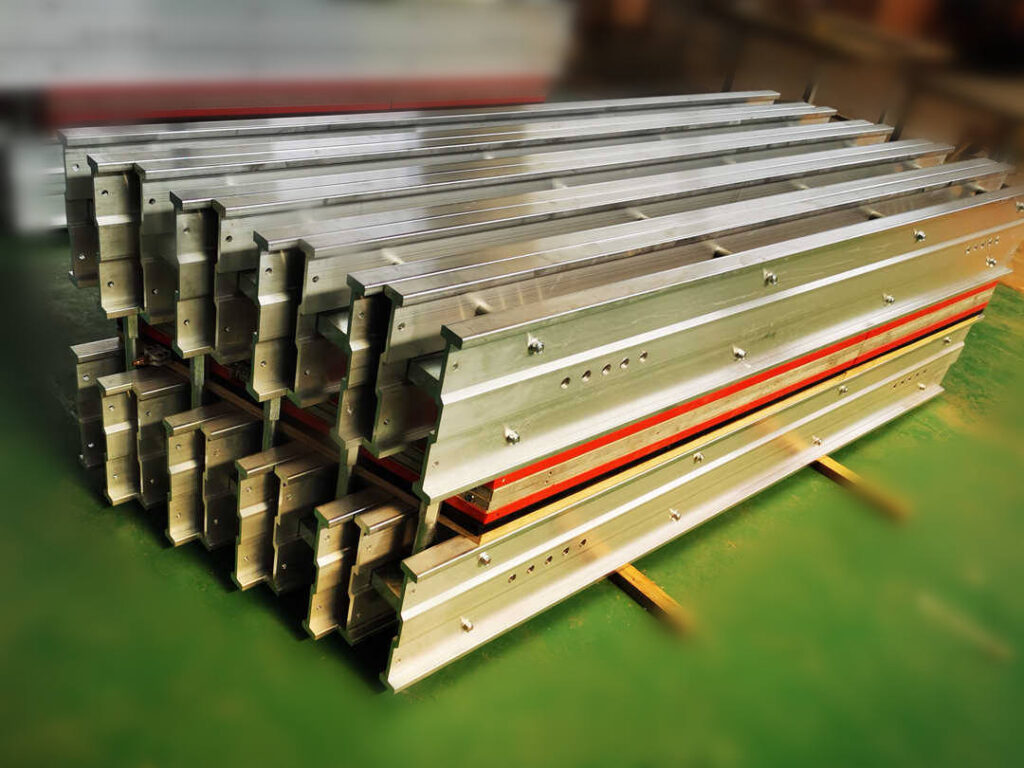

Maximizing Efficiency with Conveyor Belt Vulcanizers

In today’s fast-paced industrial landscape, the utilization of cutting-edge technology has become paramount to ensure seamless operations and maintain a competitive edge. One such technological marvel that has revolutionized material handling processes is the conveyor belt vulcanizer. This ingenious device not only enhances operational efficiency but also offers a multitude of advantages that significantly impact the bottom line of businesses across various industries.

Enhancing Operational Efficiency

Streamlined Repairs and Maintenance

The conveyor belt vulcanizer eliminates the need for time-consuming manual repairs. By utilizing advanced vulcanization techniques, it ensures a seamless bond, effectively restoring the integrity of the conveyor belt. This means less downtime and increased productivity, enabling businesses to meet demanding production schedules with ease.

Prolonged Conveyor Belt Lifespan

Regular maintenance and timely repairs with a vulcanizer significantly extend the lifespan of conveyor belts. This translates to substantial cost savings, as replacement costs are minimized. Moreover, it contributes to a reduction in environmental impact, as fewer materials are consumed in the manufacturing process.

Ensuring Workplace Safety

Elimination of Hazardous Adhesives

Traditionally, conveyor belt repairs involved the use of adhesives and solvents that posed significant health and safety risks to workers. With the advent of conveyor belt vulcanizers, these risks are virtually eliminated. Vulcanization relies on heat and pressure, ensuring a secure bond without the need for potentially harmful chemicals.

Minimized Risk of Belt Failure

The secure and durable bonds created by vulcanization reduce the likelihood of belt failure during operation. This not only protects personnel and equipment but also prevents costly disruptions in production.

Cost-Effectiveness and Sustainability

Reduced Operating Costs

Investing in a conveyor belt vulcanizer proves to be a wise financial decision in the long run. The decreased frequency of repairs, coupled with the extended lifespan of conveyor belts, leads to significant cost savings. Additionally, the device consumes less energy compared to traditional repair methods, contributing to reduced operational expenses.

Environmental Responsibility

In an era where sustainability is of paramount importance, the use of a conveyor belt vulcanizer aligns with eco-friendly practices. By minimizing the need for new belt acquisitions and reducing waste generated from repairs, businesses can significantly lessen their environmental footprint.

Conclusion: Elevating Industry Standards

Incorporating a conveyor belt vulcanizer into your operational processes is more than a strategic investment; it’s a commitment to excellence. The benefits span from heightened operational efficiency to enhanced workplace safety, culminating in substantial cost savings and environmental responsibility. As industries evolve, staying ahead requires embracing technologies that redefine standards, and the conveyor belt vulcanizer undoubtedly leads the way. Embrace this innovation, and propel your business into a future of unparalleled efficiency and sustainability.