Current Trends and Innovations in Conveyor Belt Vulcanizer Technology

In recent years, the conveyor belt industry has witnessed a remarkable surge in technological advancements, revolutionizing the way we approach belt maintenance and repairs. At the forefront of this transformation stands the conveyor belt vulcanizer technology, a critical component in ensuring the seamless operation of conveyor systems across various industries. In this article, we delve into the latest trends and innovations that are shaping the landscape of conveyor belt vulcanizer technology.

Precision and Efficiency: Automated Vulcanization Systems

Gone are the days of labor-intensive vulcanization processes. The advent of automated vulcanization systems has ushered in a new era of precision and efficiency. These cutting-edge systems leverage advanced robotics and AI algorithms to precisely control the application of heat and pressure during the vulcanization process. This not only ensures a uniform and high-quality splice but also significantly reduces downtime, ultimately leading to substantial cost savings for businesses.

Smart Sensors and Predictive Maintenance

Predictive maintenance has become the cornerstone of modern industrial operations, and conveyor belt vulcanizer technology is no exception. Smart sensors integrated into vulcanization equipment now have the capability to monitor various parameters in real-time. From temperature and pressure to belt tension and alignment, these sensors provide crucial data insights. By leveraging predictive analytics, maintenance teams can proactively address potential issues before they escalate, resulting in increased uptime and prolonged belt lifespan.

Environmentally Conscious Vulcanization Materials

With an increasing emphasis on sustainability and environmental stewardship, the conveyor belt industry is witnessing a shift towards eco-friendly vulcanization materials. Manufacturers are now developing vulcanizing agents that are not only highly effective in bonding conveyor belts but also have a reduced environmental impact. These green alternatives are paving the way for more sustainable and responsible conveyor belt maintenance practices.

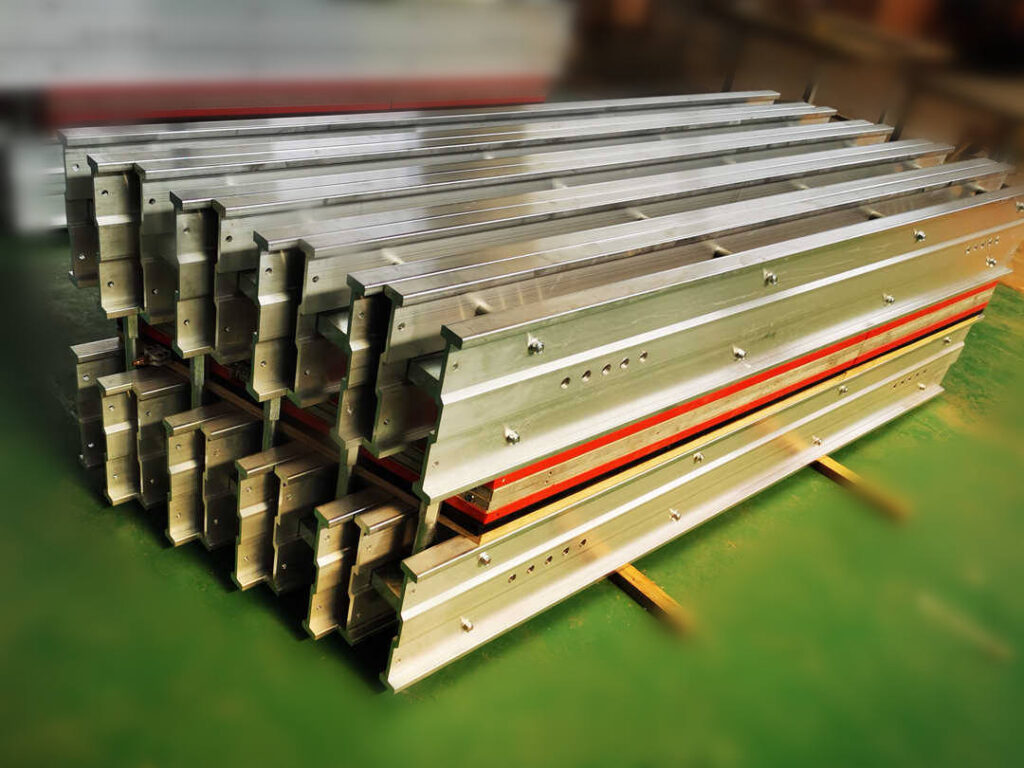

Portable Vulcanization Solutions for On-Site Repairs

In today’s fast-paced industrial landscape, minimizing downtime is of paramount importance. Portable vulcanization solutions have emerged as a game-changer for on-site repairs. These compact, mobile units empower maintenance teams to swiftly address belt splicing and repairs directly on the conveyor line. This eliminates the need for costly transportation of belts to off-site facilities, resulting in significant time and cost savings.

Integration with IoT and Industry 4.0

The integration of conveyor belt vulcanizer technology with the Internet of Things (IoT) and Industry 4.0 principles is redefining the way we monitor and manage conveyor systems. Real-time data from vulcanization processes can now be seamlessly integrated into broader operational platforms, allowing for comprehensive process optimization. This interconnectedness enables a holistic view of conveyor system performance and facilitates data-driven decision-making.

Continuous Research and Development: Staying Ahead of the Curve

In an ever-evolving industry, staying at the forefront of technology is paramount. Manufacturers of conveyor belt vulcanizer technology are investing heavily in research and development to push the boundaries of what’s possible. This commitment to innovation ensures that businesses have access to state-of-the-art solutions that are tailored to meet the dynamic demands of modern industrial operations.

In conclusion, the conveyor belt vulcanizer technology landscape is undergoing a profound transformation, driven by a relentless pursuit of precision, efficiency, and sustainability. With automated systems, predictive maintenance capabilities, eco-friendly materials, portable solutions, and seamless integration with IoT, the future of conveyor belt maintenance looks promising. By embracing these trends and innovations, businesses can not only optimize their operations but also contribute to a more sustainable industrial ecosystem.

If you want to read more information about how to boost traffic on your Website just visit –> The Insider’s Views