BOX Series Two Pieces Frame Style Cconveyor Belt Vulcanizer

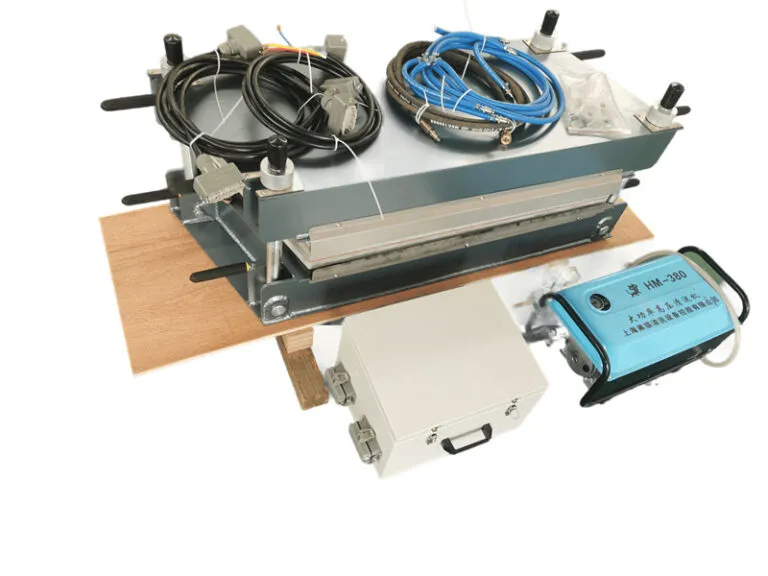

- Two lightweight frames made of welded high-strength aluminum alloy form the upper and lower parts of the press.

- The two sides of the two frames are equipped with handles with rubber sheaths for easy handling;

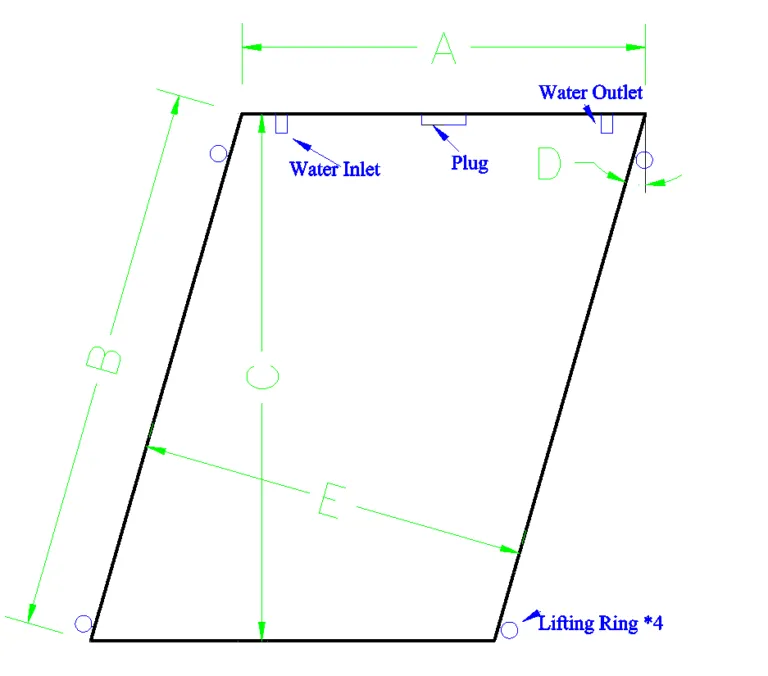

- Larger models can be equipped with hoisting rings.