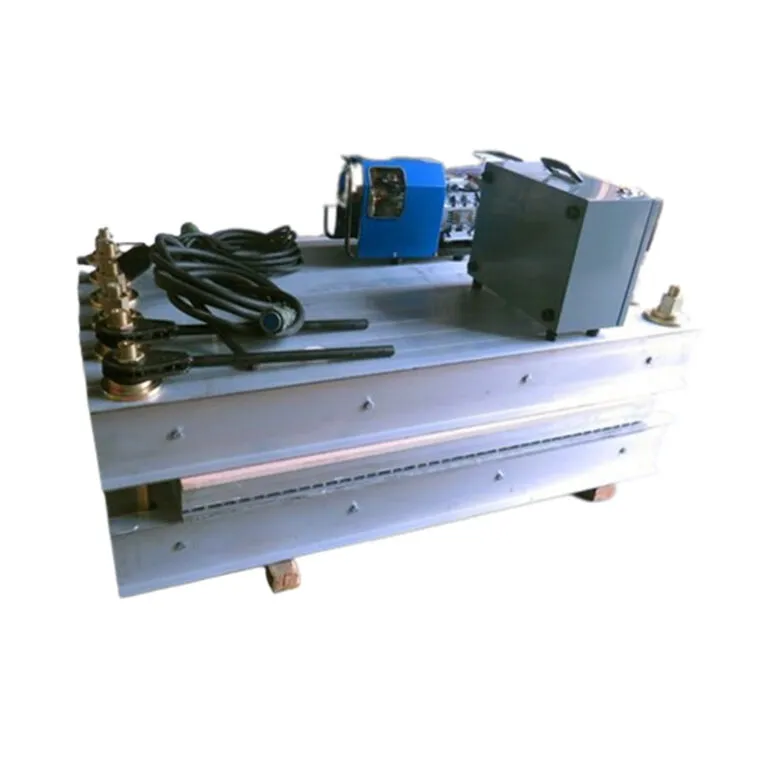

Classic Sectional Vulcanizing Press

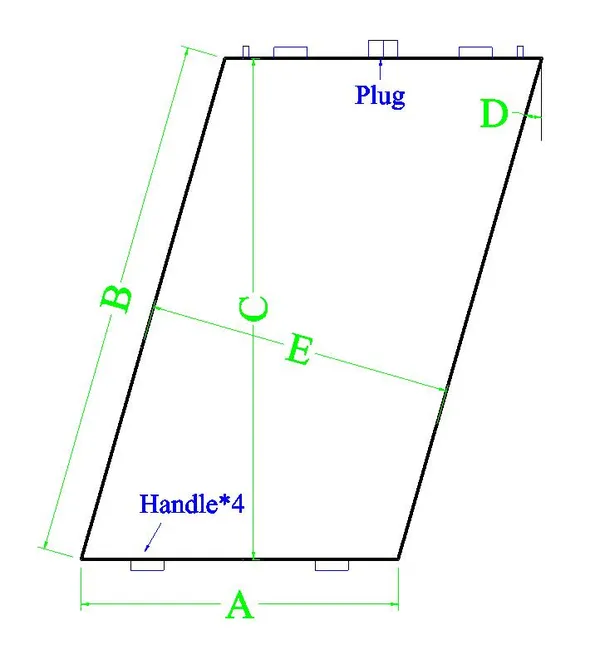

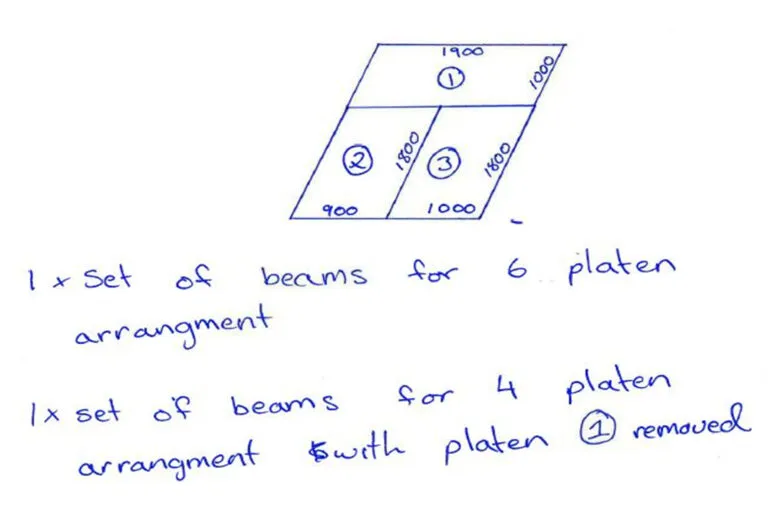

The Classic Sectional Vulcanizing Press is a durable conveyor belt vulcanizer that has been around for over 40 years. Its main feature is the use of a sturdy A-type crossbeam. Over the years, the Classic Sectional Vulcanizing Press has undergone several developments, and there are now various configuration options available.

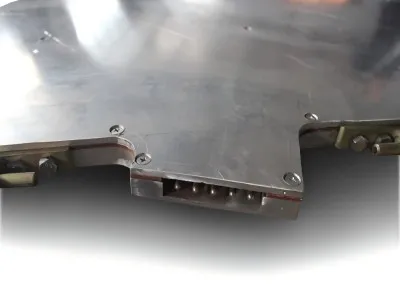

- Heating plates can be heated using traditional heating elements or silicon heating elements. There are also two types of silicon heating elements available - lightweight design or sandwich-style heating plates, which are similar to the ASVP vulcanizer.

- The pressure system can use the traditional aluminum base plate with a metal frame and screw press plate or the modern rubber pressure bag.

- Although a manual pressure pump is sometimes used, most customers opt for an electric pressure pump that, when used with a quick water cooling system, significantly reduces the time required for conveyor belt splicing.